4 Ways to Decarbonize the Waste Industry

Achieving net-zero requires more than green energy—waste management is critical. Canadian businesses can cut emissions by improving waste diversion, electrifying fleets and operations, and using carbon offsets, while embracing innovative technologies to create a sustainable, circular economy.

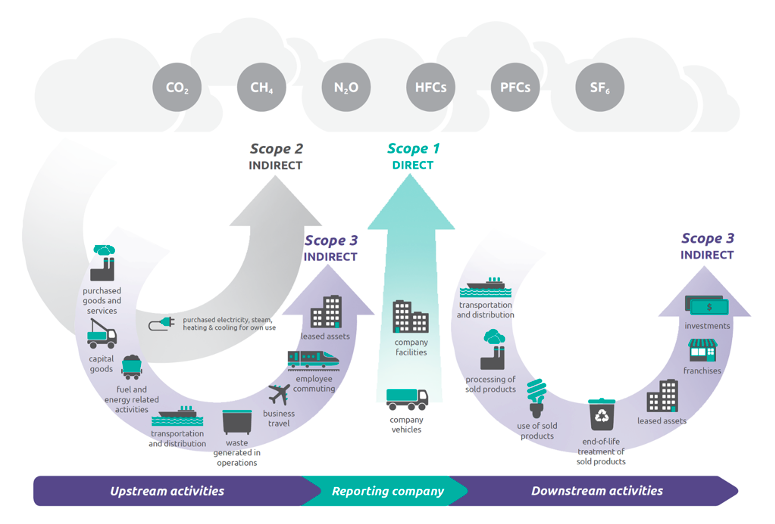

The recent surge in climate consciousness has driven Canadian businesses to strive for net zero. However, switching to green energy isn’t the endgame. In the food service industry alone, greenhouse gas (GHG) emissions produced by waste make up 15.3% of their total carbon footprint and 80% of their scope 3 emissions (i.e., indirect emissions). In other words, once a food service business goes green with its energy, 80% of the remaining emissions come from waste. Clearly, our current waste management practices are falling short. To start, we can implement four decarbonization methods we’ve been exploring at Rethink Resource.

1. Divert as Much Waste as Possible from Landfills using Low-Emission Methods

Across Canada, non-residential sources account for 62% of undiverted waste, producing an estimated 14 megatonnes of GHG emissions in 2022 alone. Reducing these numbers requires a more innovative approach to waste diversion.

Keep Organics Out of Landfills at All Costs

Although it might seem harmless to leave a banana in the landfill waste bin, it fuels one of the world’s most potent contributors to climate change. Organic materials sent to landfill create methane, a GHG with 25 times the warming power of carbon dioxide, which is 80 times more powerful during its first 20 years in the atmosphere. Methane accounts for an estimated ⅓ of global warming, and atmospheric methane levels continue to increase every year. In Canada alone, decaying food in landfills produces 56.5 million tonnes of methane annually. And if we consider that 17% of national methane emissions in 2022 came from Canadian landfills, we need to reconsider our waste diversion practices. It’s not always easy to find clear information about the footprint of waste diversion practices. That’s why we’re working on a research project as part of the Low Carbon Readiness Program, offered through Mohawk College’s Centre for Climate Change Management (CCCM), to quantify Scope 3 emissions of waste diversion and management processes.

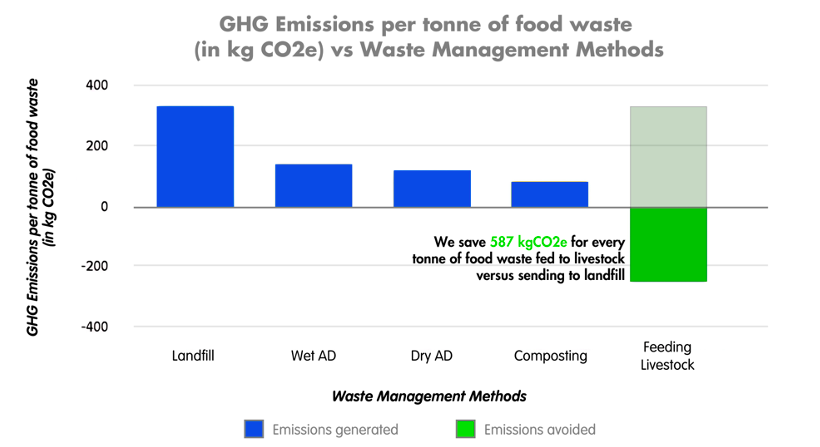

At Rethink Resource, we minimize our emissions by feeding organic waste to livestock before employing other waste management processes. As a result, we save 587 kg CO2e for every tonne of food waste diverted from landfills and fed to livestock. We use anaerobic digestion for most of the remaining organic waste, which is about 60% less carbon-intensive than landfill disposal.

*with the exception of Feeding Livestock data, which was collected using the current literature on Canadian farm and crop emissions.

Investing in advanced waste management technologies is one of the most effective ways to keep organic materials and plastics out of landfills. Various AI applications are revolutionizing the precision with which waste is sorted, collected, and visualized on a broad scale.

At Rethink, we’re exploring operations with Waste Robotics to sort waste using robotic arms, and using AI-driven computer vision to scan and identify the type and quantity of waste collected. Combining these technologies with our Waste Emissions & Accounting Software will provide customer and location-specific waste data by type, volume, and emissions footprint. Introducing these types of digital solutions into the waste processes can potentially reduce global carbon emissions by 15% by 2030.

“Investing in advanced waste management technologies is one of the most effective ways to keep organic materials and plastics out of landfills”

-Shane Harker

How You Recycle & Upcycle Matters

Once you’ve diverted as much waste as possible from landfills, you can further decarbonize your process by opting for low-emissions recycling and upcycling pathways. You can look to the Zero Waste Hierarchy and Food Waste Hierarchy as guiding principles for your practices like we do at Rethink. These internationally peer-reviewed guides prompt us to do everything possible to get waste back into the materials cycle, creating closed-loop systems and minimizing harmful discharges.

How the Rethink Resource team puts these principles to work:

With the help of our recycling partner, Greenwell Plastics, we upcycle landfill-bound plastics into durable plastic lumber and furniture.

We feed grocery produce waste and spent brew grains not fit for human consumption to livestock.

We collaborate with EFS Plastics, a 100% post-consumer plastics recycler, to recycle end-of-life plastics. These are turned into post-consumer recycled resins (PCR), which reduce GHG emissions by at least 67% compared to virgin resins. For Polypropylene, every 1000 lbs of PCR used in place of virgin resins reduces CO2 emissions by 71% (239 kg for PCR vs. 835 kg for virgin resin).

2. Electrify Your Fleet

Switching to an electric fleet comes with big long-term savings but hefty capital investments, so we suggest starting small. We started electrifying in January 2022 and have since reduced our operating emissions by 34,003 kg CO2e by electrifying 22% of our fleet, and are working towards a 100% electric vehicle fleet by 2028. Remember that when going electric, you may have to adjust your operations to ensure your EV’s capabilities support the transported weights.

Take Advantage of Canadian Clean Fuel Credits

Luckily, Canada’s Clean Fuel Credit (CFR) initiative helps offset some of the up-front costs of going electric. The CFR is designed to provide financial incentives to companies and organizations adopting renewable energy fleets. That means that Canadian fleets adopting RNG, electricity, or green hydrogen are eligible for CFR benefits. We’re working closely with Lion Electric, a Canadian zero-emission vehicle manufacturing company, to electrify our commercial fleet.

3. Switch to Electric or Renewable Energy Alternatives for Other Daily Machinery & Operations

Transforming your daily operations with electric or renewable energy alternatives can significantly reduce your carbon footprint; this includes using electric forklifts, heaters, heat pumps, and pressure washers.

At Rethink Resource, we’ve recently replaced fossil-fuel-powered forklifts and pressure washers with electric alternatives. And, yes, the impact is noteworthy! Switching from a diesel-powered forklift to an electric model with a high-capacity battery can reduce carbon dioxide emissions by 7000 kg annually. Electrifying any part of your systems will also result in lower maintenance costs and improved working conditions due to reduced noise pollution and better air quality.

“Transforming your daily operations with electric or renewable energy alternatives can significantly reduce your carbon footprint; this includes using electric forklifts, heaters, heat pumps, and pressure washers”

-Shane Harker

4. Offset Unavoidable Carbon Emissions with Carbon Credits

Despite our best efforts to reduce emissions, some GHG production is unavoidable. In these cases, environmental impact can be mitigated with credible carbon offsets verified by reputable certifying bodies, like Gold Standard.

Understanding Emissions Scopes

At Rethink Resource, we’ve implemented a comprehensive strategy to address all emission scopes. That means tracking all Scope 1 and 2 GHG emissions, which allowed us to achieve net-negative status for these in 2022 by offsetting unavoidable emissions with certified carbon credits supporting the Great Bear Rainforest in British Columbia.

We’ve also started quantifying our Scope 3 emissions and developing software to measure our clients’ Scope 3 emissions. Our goal is to accurately track and offset all of Rethink Resource’s Scope 1, 2, and 3 emissions while also providing emissions reporting and offsetting services for our entire client base. The idea is to use this technology to help clients visualize their overall footprint and get inspired to reduce the impact of their operations. We’re committed to reporting all emissions and achieving net-zero emissions by March 31st, 2025.

It’s Time to Rethink Waste

Our current “out of sight, out of mind” approach to waste isn’t serving us anymore. The environmental costs of outdated waste management practices are clogging the atmosphere, which means it’s time to view waste not as an end product but as a resource in a circular economy. We recognize that emissions data isn’t going to be perfect. But we have the technology to make a significant difference. As global pressure to reduce carbon footprints intensifies, businesses already invested in low-carbon waste processes will be ahead of the curve. Starting now means positioning your business for long-term success while decarbonizing to give humanity a fighting chance.