Addressing Critical Metal Shortages for a Sustainable Future

Mohammad Doostmohammadi, Founder & CEO at pH7 Technologies, emphasizes the role of critical metals in the energy transition. Platinum group metals and copper are required for hydrogen production and electrification, and we need solutions to address supply shortages. Innovations aimed to extract and reuse metals from waste are discussed.

The Energy Transition Problem is a Critical Metals Problem

The need for a comprehensive energy transition has never been more certain. Development of completely green sustainable power solutions, implementation of net zero industrial processes, and global decarbonization are an absolute necessity – not just for progress, but for survival. While (thankfully) innovations in energy transition tech have gained substantial momentum over the last decade, in the course of growth, they have revealed urgent underlying challenges – metals. Key critical metals for green energy technology development and operations – like platinum group metals (PGMs) used in hydrogen fuel production/use, or copper used as the world’s go-to electrification – are in deficit. So, while new technology and sustainable solutions begin to accelerate to market, to enable their full potential the global community will have first to overcome supply shortages – something feasible only through a dedicated commitment to recycling, circular economic principles, and innovative extraction of materials previously untapped.

“Key critical metals for green energy technology development and operations – like platinum group metals (PGMs) used in hydrogen fuel production/use, or copper used as the world’s go-to electrification – are in deficit”

Mohammad Doostmohammadi

Circular Economy as a Pathway for PGM Supply Chain

Hydrogen is one of the most viable methods by which to provide completely green energy. When produced using a net-zero process, it results in virtually zero carbon emissions and possesses more than three times the energy per unit mass contained in petrol (140 MJ/kg compared to 44 MJ/kg). However, without PGMs there is no (realistic) scalable hydrogen solution. PGMs like platinum, ruthenium, and iridium serve as critical catalysts in the hydrogen supply chain from production to transportation and the final consumption. As examples, the stark reality is by 2030 it is speculated that platinum will see a deficit of more than 16% (missing 20-30 tonnes) while iridium may see as bad as a 40% deficit.

So, a reasonable question – why not just produce more? Unfortunately, increasing production could actually be more detrimental to the environment given the large carbon cost associated with mining, smelting, refinement, and logistics. Also, the metals are scarce in the earth and more mining is not realistically feasible as there is no more of these metals to address the needs for the energy transition.

A more amenable (and low cost) option is a circular economic, recycling-based model that leverages existing PGMs after their first use life. For example, in 2019 alone, more than 50 million metric tonnes of electronic waste (e-waste) were generated – of which an estimated $2.5 billion worth of PGM could have been recovered equating to a speculated 10s of tonnes of platinum, as well as other materials.

This showcases a strong demand for PGM recycling – however, traditional extraction processes have resulted in significant wastewater generation, huge power demands, and its own set of toxic emissions, unfortunately negating much of the sustainable aspect of this avenue.

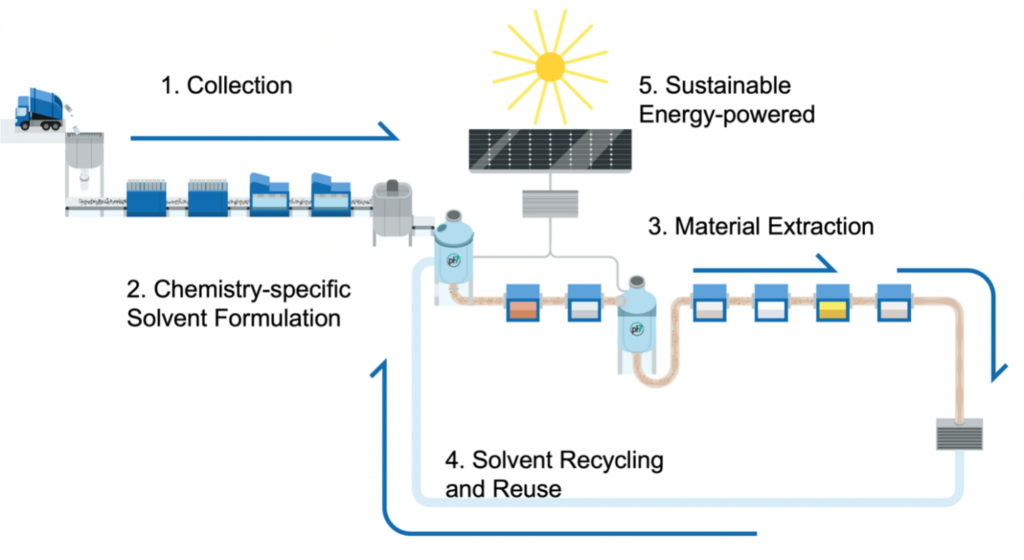

A key pathway forward – and what pH7 has been dedicated to – is developing clean, sustainable, and scalable chemical processes to extract PGM materials from waste materials, which represents an almost ideal solution to this materials problem. If net zero can be maintained, then instead of more unsustainable production of PGMs, materials can be cyclically reused within hydrogen (and other energy transition) technologies over and over again, fulfilling otherwise potentially unattainable demand signals and enabling at scale adoption of crucial green power.

Improving Mine Production by Unlocking Copper From Low-Grade Waste

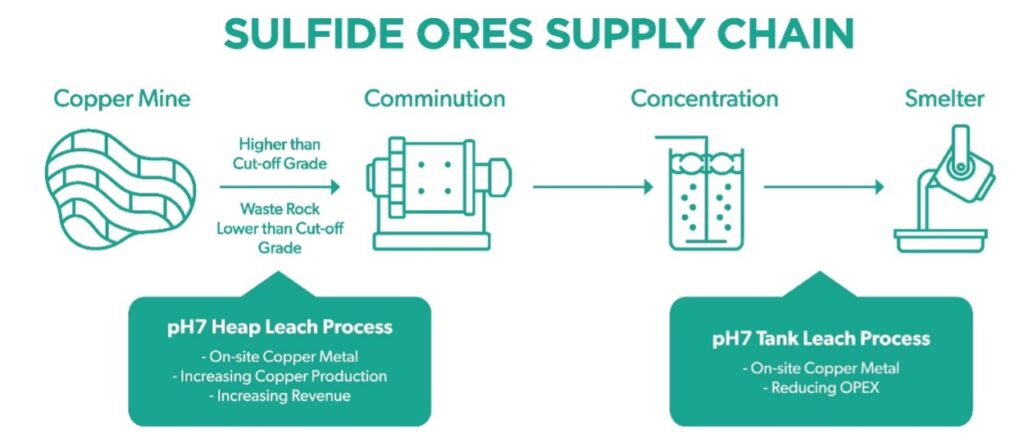

It’s no surprise that copper is nearly synonymous with electronics, and for the same reasons (phenomenal conductivity, malleability, and low cost), copper is also key to all things green technology. Similar to PGMs, there is also already a global supply deficit, only expected to grow and hit about 17% by 2030. For reasons akin to PGMs, it is also just as difficult to simply “produce more” – and instead, the community as a whole must look for other paths to alleviate need or supplement supply. While chemical extraction from first-life materials enabling recycling and circular economics provides one possibility for copper as well as PGMs, another opportunity lies within low-grade waste sources that currently rarely see even first-use.

To oversimplify, mining copper is a complex process of ore extraction, crush-up, mineral isolation, and refinement. The ore sources are various copper-iron-sulfides embedded in rock, and each step is meant to isolate and refine material into a purified copper product. However, yield and efficiency are understandably imperfect, leaving as much as 50% of available copper “locked up” in low-grade ore, which has traditionally been uneconomical to extract, often requiring toxic and costly chemical processing. Finding a tractable way to access this supply would be incredibly beneficial to the community, benefitting the development of green technologies while also directly supporting mining and enabling more sustainable operations. pH7 has tried to tackle this problem by developing a chemical solvent (in-family to formulations used in our waste recycling process) for use in heap-leaching of low-grade waste-rock and tailing. This extracts and isolates copper in solution from non-useful minerals and “unlocks” otherwise wasted supply. Further committing to circular economics and sustainability, the lixiviant is reusable over and over again following a regeneration process – a byproduct of which is hydrogen, ready for use as fuel.

“Finding a tractable way to access this [copper] supply would be incredibly beneficial to the community, benefitting the development of green technologies while also directly supporting mining and enabling more sustainable operations”

Mohammad Doostmohammadi

Green Energy Through the Sustainable Extraction of Would-be Wasted Metals

There is some philosophical symmetry to it all. One of the biggest challenges to energy transition is critical metal deficit, and one of the best solutions to that deficit is a more circular economy, more sustainable extraction/recycling, and closed-loop net zero practices in using and reusing metals. So, in a way, the key to energy transition is to be more sustainable not just at the level of technology, but to start all the way at the foundation with the fundamental materials used – be green from the bottom up.

References:

- Net zero emissions by 2050 scenario (NZE) – Global energy and climate model – Analysis. (n.d.). Retrieved from https://www.iea.org/reports/global-energy-and-climate-model/net-zero-emissions-by-2050-scenario-nze

- Hydrogen: Enabling a Zero Emission Society. Energy central. (2022). Retrieved from https://energycentral.com/ system/files/ece/nodes/579157

- Platinum Group Metal Catalysts: Supply Chain Deep Dive Assessment. US Dept of Energy. (2022, Feb 24). Retrieved from: chrome-extension://efaidnbmnnnibpcajpcglclefindmkaj/https://www.energy.gov/sites/default/ files/2022-02/PGM%20catalyst%20supply%20chain%20report%20-%20final%20draft%202.25.22.pdf

- PGM Market Report. Johnson Matthey. (2023, May). Published Johnson Matthey PLC

- Lux research. (n.d.). Retrieved from https://members.luxresearchinc.com/

- PGM reserves worldwide by country 2022. (2023, January 31). Retrieved from https://www.statista.com/ statistics/273624/platinum-metal-reserves-by-country/

- Enough with the E-waste”. ESG Investor. (2023, July 26th ). Retrieved from https://www.esginvestor.net/enoughwith-the-e-waste

- Copper mining and processing: Processing copper ores. (2021, March 17). Retrieved from https://superfund.arizona.edu/resources/learning-modules-english/copper-mining-and-processing/processing-copper-ores

- Yan, Y. (2023, July 20). Copper crunch: The race against time for the basic metal of energy transition. Retrieved from https://medium.com/@yan.yan_62880/copper-crunch-the-race-against-time-for-the-basic-metal-of-energy-transition-e87560ef28ec