Carbon Engineering is capturing carbon, and the world’s attention

It seems almost fantastical that there is a thing we know must be done in order to save the planet and we’re worried about it being a bit pricey, but that’s how things are.

In recent year climate modellers have agreed that in order to meet the temperature goals of the 2016 Paris Agreement, reducing emissions, no matter how aggressively we do it, will not be enough. Removal of existing CO₂ from the atmosphere is necessary and yet there’s been a lot of talk about the cost of large-scale carbon capture.

To put this in perspective, imagine that this is a movie we were all watching. Imagine that our heroes, after many close calls and countless one-liners, have worked out how to thwart the alien invasion that will doom the planet. It’s a simple plan, really; Will Smith will pilot a captured flying saucer up to the alien mothership so Jeff Goldblum can connect an Apple laptop to the extraterrestrial computer system and upload a virus that will bring down the craft’s impenetrable force field finally rendering the ship vulnerable to attack. This is a plan that cannot fail but suddenly we see them freeze.

“Wait? What are we doing guys?.” Jeff Goldblum says quietly, “Sure, I can rig up a flying saucer to take a USB cable, but that would be expensive. I can’t justify the cost when there’s still a chance this alien invasion will just blow over.”

“You’re right!” Will Smith says, “Why are we talking about ‘buying a soldering iron’ and ‘launching fighter jets’ when we could just learn to adapt to the alien conquest of Earth.”

“I hear the alien death rays have opened up the northwest passage” says President Bill Pullman, sticking his head through the door, “this could have real benefits for trade. I think I jumped the gun with all that ‘We can’t be consumed by our petty differences’ and fight for our right to live. To exist’ stuff.”

Fade to black. Roll credits. The reviews would be terrible but that’s the script we’ve been writing, global warming-wise. The cost of removing heat-trapping gases from the atmosphere has been a stumbling block in reducing the huge threat of climate change but enter companies like Carbon Engineering (CE), one of the exciting new startups in the “direct air capture” industry that are setting out to help save the world, cost effectively.

The implications of this DAC technology on climate strategy are twofold – it allows the removal of existing CO₂ from the air to counteract emissions too challenging or costly to eliminate at source, and enables the production of clean transportation fuels that can significantly reduce transportation emissions.

CE was founded in Calgary, Alberta in 2009, the outcome of academic work conducted on carbon management technologies by Professor David Keith’s research groups at the University of Calgary and Carnegie Mellon University. Their mission: to remove carbon from the air at scale, and help reverse climate change worldwide by developing technology that enables atmospheric carbon capture on a global scale and right now their Direct Air Capture (DAC) technology is showing the world what a cost-effective, scalable solution for atmospheric CO₂ look like.

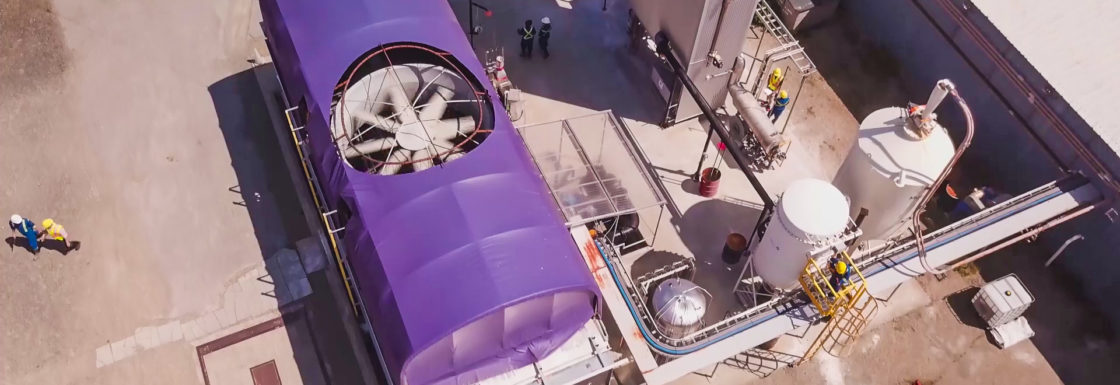

In 2015, CE moved its headquarters to Squamish, British Columbia, to start construction of an end-to-end DAC pilot plant, testing and optimisation efforts, and when running, as it currently is, the plant captures and purifies roughly 1 ton of CO₂ per day.

DAC technology works by processing atmospheric air, removing CO₂ and purifying it. CE’s DAC technology does this in a closed loop where the only major inputs are water and energy, and the output is a stream of pure, compressed CO₂. This captured CO₂ offers a range of opportunities to create products and environmental benefits. It can be permanently sequestered underground to directly contribute to negative emissions required to reduce the effects of global climate change, used in the production of clean liquid transportation fuels, or utilised for Enhanced Oil Recovery or to produce materials and chemicals.

The implications of this DAC technology on climate strategy are twofold – it allows the removal of existing CO₂ from the air to counteract emissions too challenging or costly to eliminate at source, and enables the production of clean transportation fuels that can significantly reduce transportation emissions.

Once built, individual DAC facilities can capture one million tons of CO₂ per year each. That’s the annual emissions of 250,000 average cars and CE is now commercialising its DAC technology through integration with the company’s AIR TO FUELS™ process, which uses water electrolysis and fuels synthesis to produce clean liquid fuels. This process combines renewable generated hydrogen with CO₂ captured from the atmosphere through DAC, to produce ultra-low carbon intensity hydrocarbon fuels.

The transportation sector is searching for next generation technologies and fuels that will enable compliance with the deep emissions reduction targets agreed to in the COP21 Paris Accord and other similar bilateral and multilateral agreements. Fuels synthesised from atmospheric CO2 offer an attractive and scalable complement to existing options — like electric vehicles — which may well be need for long haul marine and air travel.

The recycling of existing atmospheric CO2, put CE’s fuels among the lowest carbon intensity fuels available. Produced with an ultra-low life-cycle carbon intensity that is 90 per cent less than fossil fuels and less than half of typical biofuels. CE’s fuels require 100 times less land use than today’s biofuels and therefore do not impact food security. Furthermore, CE’s synthetic fuels are cleaner burning than those refined from fossil crude, and in turn help reduce air pollution as well as GHG emissions.

While currently more expensive than the production cost of fossil fuels — An AIR TO FUELS™ plant can generate fuels or blend-stocks for costs around $1.00 per Litre — renewable fuel standards regulations are expected to continue to be adopted around the world and tighten in response to climate commitments.

In fact it’s long been technically possible to synthesise liquid fuels from hydrogen and CO2 by using mature technologies like Fischer-Tropsch and Exxon’s Methanol-to-Gasoline for some time now, but it wasn’t cheap. Recent reductions in the cost of carbon neutral electricity and the development of low-capital cost electrolysis are quickly reducing the cost of carbon neutral hydrogen. This, coupled with CE’s industrial-scale Direct Air Capture of atmospheric CO2, has brought carbon-neutral synthetic fuels to economic viability.

A just released report from the National Academy of Sciences says that by mid-century, we need to be removing about 10 billion metric tons — about twice the yearly emissions of the U.S. — of carbon dioxide from of the air annually and now that might be possible.

It’s as if now we’re watching Jeff Goldblum connect a refurbished Dell to the extraterrestrials’ computer system, not a fancy new Mac, saving the world from the menace looming all our heads in a more environmentally conscious way.. Of course that this setup it’s more affordable doesn’t mean we should become nonchalant and invite more destruction upon the Earth, we must still shift towards a low-carbon economy, but the planet is facing a crisis we face now and CE has what it takes to get the job done.