Clean50’s Clean Tech Nominees for 2024 – Part 3 of 8

This week featuring Graphite Innovation and Technologies Inc., Exhale Aerosystems, GEOptimize Inc., Evoco Ltd., Groupe PureSphera Inc., Mangrove Lithium, and Li-Metal Corp.

Each year the Clean50 Awards attract more worthy nominees than we can possibly include on our list when we release it each fall (this year September 28th), and that’s an incredible shame – because this year we have 60 incredible nominees in the Cleantech and R&D categories alone. It’s great to know that clean tech innovation is alive and well in this country!

But innovation is not enough: Organizations and individual Canadians need to make the conscious choice to support made-in-Canada innovation – and buy Canadian wherever and whenever they can. Because here’s the thing: the incredible sums of money Joe Biden has invested in US based clean tech and the tax advantages he has conferred on clean tech investors means that US based clean tech companies are rich with cash – and they can afford to buy up Canadian competitors, and then take the intellectual property – and the jobs – and the revenues – to the USA. So we’re trying to do our part and show you 60 companies doing amazing stuff – and we hope you’ll do your part – and BUY some of it!

As we go through this process, we’ve been amazed at where some of our clean tech innovation is coming from: It’s not just start ups and university labs. We’re featuring lots of those, for sure – but also a company capturing kelp from the seabed – turning it into compostable plastic, and another recycling abandoned plastic fishing nets into brand new plastic, and a company which has figured out a way to make boats really really slippery. How does that help? you ask… you’ll find out – if you keep reading!

We promise – each of the 8 articles in this series will open your mind to some seriously cool possibilities! Congratulations to all of our nominees!

Graphite Innovation and Technologies Inc.

Clean 50 Nominee Marciel Gaier, Co-Founder and CTO

Dartmouth, NS

What does the product do?

GIT offers biocide-free, highly durable, and ultra-low friction foul release propeller and hull coatings for vessels of all kinds, offering shipping operators an extremely effective way to improve and maintain CII rating over the drydocking cycle. The advanced coatings demonstrate measurable improvements in propulsion, reduced drag and fuel efficiency as well as durability, reducing maintenance time, while maintaining the propulsive efficiency of the propeller and reducing damage due to cavitation, thereby lowering noise emissions.

The coatings have been proven in extensive trials and have been applied to almost 100 commercial ships worldwide, reducing the release of copper biocides with the target to avoid 1M Kg of copper biocides into our ocean and 4.5M tons of CO2 to the air by 2030.

Who should buy it? Ship owners and operators looking to lower their carbon footprint, improve fuel efficiency, and reach CII and EEXI targets to achieve IMO compliance.

Exhale Aerosystems

Clean 50 Nominee Crystal Kuyumcu, Founder and CEO

Whitby, ON

What does the product do? The transportation sector is struggling to decarbonize and synthetic fuel manufacturers are in need of a clean CO2 feedstock to create their products. Exhale Aerosystems aims to solve both these problems and revolutionize the transportation industry by using our Carbon Removal Systems (CRS) on transportation vehicles such as trucks, trains, and aircrafts. The system diverts the high-velocity air travelling alongside transportation vehicles in motion into our system where our solid sorbent filter captures the CO2 from the atmosphere and releases the clean air.

Who should buy it? Exhale Aerosystems will sell our technology to fleet operators who are paid in cash or carbon credits for the CO2 their vehicles capture, and we will sell the clean CO2 feedstock to carbon utilization companies that make valuable products such as Sustainable Aviation Fuel. A fleet of just ten transport trucks has the potential to capture 1200 tons of CO2 each year and earn a revenue of $240,000 CAN from their existing assets travelling their existing routes.

GEOptimize Inc.

Clean 50 Nominee Ed Lohrenz, Founder and Vice President

Winnipeg, MB

What does the product do? Ensure is a ground heat exchanger (GHX) monitoring system that predicts the future temperature of a GHX and controls the operation of discretionary heating or cooling loads. Discretionary loads add or remove heat from the GHX to ensure the temperature stays within efficient operating parameters. The ability to manage GHX temperatures allows a reduction in size and capital cost, improves long-term reliability and efficiency of the heat pumps connected to it.

Who should buy it? Building owners wishing to electrify their buildings and eliminate the use of fossil fuels.

Evoco Ltd.

Clean 50 Nominee Jason Robinson, CEO

Toronto, ON

What does the product do? What if the materials used in the products we walk on, sleep in and drive in, could be made with significantly less environmental impact, while maintaining high-performance standards? Steps in Evoco, a material innovation company that replaces oil with plants and helps brands create sustainable products by defossilizing the material value chain. Its latest patented technology, FATES™, is a high-performance eco-foam that reduces carbon emission by up to 70% vs oil-based foam, and has a minimized end-of-life impact through its advanced biodegrading and detoxifying properties.

Who should buy it? FATES™ has already been adopted by global footwear brands like Vans, Keen and Timberland. Evoco’s innovation roadmap includes a plant based leather alternative, plastics, adhesives and 3D printing. By putting plants at the center of its platform, Evoco leverages a variety of plant feedstocks to develop a wide range of formulations resulting in limitless applications.

Groupe PureSphera Inc.

Clean 50 Nominee Jean Shoiry, President and Chairman

Becancour, QC

What does the product do? PureSphera promotes the optimal management of end-of-life (EOL) refrigerated appliances such as air conditioners, fridges, freezers, and dehumidifiers. Their unique technology captures 99.9 % of the refrigerants (freons and halocarbons) from appliances and foam insulation, and recycles 96.8% of appliance components. Their process reduces 2.7 times more GHGs than the regulatory requirement, reducing GHG emissions by more than 1.8 million tons of CO2eq since its startup. They also resell refurbished appliances and sell spare parts for reparation. PureSphera’s operations prompted legislation for proper management of EOL refrigerated appliances and contribute to the carbon offset market.

Who should buy it? Retailers that have implemented a PRO (Producers Responsibility Organization) that are the main clients of PureSphera Inc.. Energy Efficiency programs that promote the early retirement of old fridges and freezers also benefit from their services.

Mangrove Lithium

Clean 50 Nominee Saad Dara, CEO and Founder

Vancouver, BC

What does the product do? Mangrove’s lithium refining process converts lithium extracted from brines, hard rocks, clays, and recycled batteries into lithium hydroxide or lithium carbonate for use in battery manufacturing. Mangrove’s patented electrochemical technology produces a more pure battery-grade lithium with no waste by-products and less energy input at a lower cost for their customers. Mangrove helps create domestic lithium supply chains and gain energy security by decentralizing the lithium refining step and co-locating with lithium producers, battery manufacturers and recyclers.

Who should buy it? Upstream lithium producers, such as lithium brine and hard rock producers, battery/cathode manufacturers, or battery recyclers.

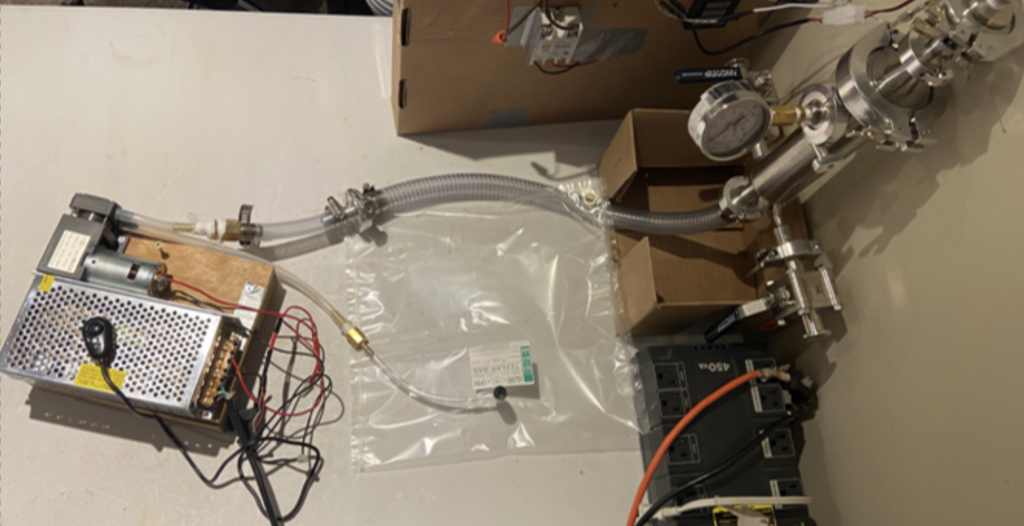

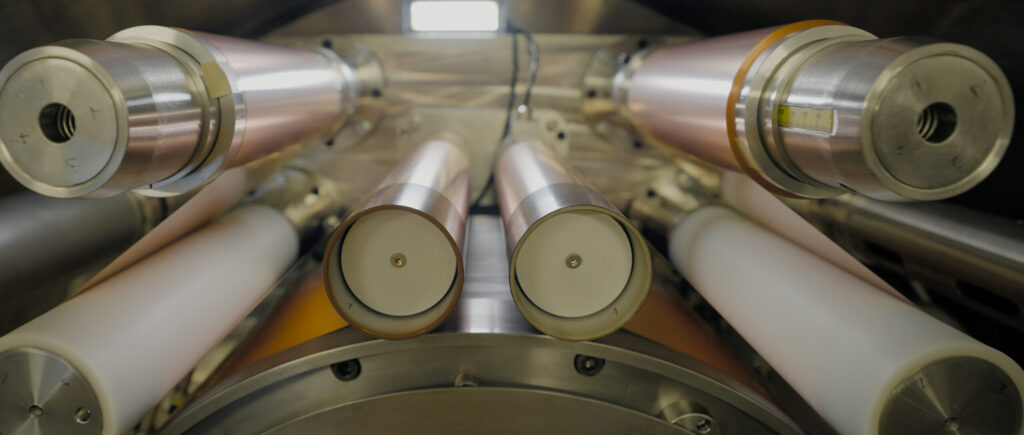

Li-Metal Corp.

Clean 50 Nominee Maciej Jastrzebski, CTO and Co-Founder

Markham, ON

What does the product do? Li-Metal’s technologies enable battery developers to produce the batteries that will power the next generation of EVs and electric aircraft. Our patented lithium metal technology is cost-effective and avoids producing 5 tonnes of harmful chlorine gas per tonne of lithium metal compared with traditional processes. Our approach to battery anode production eliminates the need for graphite and minimizes the amount of metal used, which improves safety and limits waste. We operate the highest intensity PVD technology in our industry, producing thousands of metres of high-performance materials for next-generation batteries per year

Who should buy it? Automakers and battery developers