Cleantech Chronicles Part 5 – Clean Water + Material Inputs

Last month, we set out to feature the most exciting Canadian cleantech we’ve encountered in our search for this year’s Clean50. So far, we featured over 30 companies leading innovation in Canada, from hydrogen storage breakthrough technologies to AI-powered wildlife monitoring success stories, and more. We’ve seen the future, and it’s bright—and undeniably green.

This week, as we wrap up our five-part series, we’re turning our attention to some of the most pressing environmental challenges of our time, including forever-chemicals, finite industrial resources, and microplastics, all with far-reaching impacts on human and planetary health. What better way to close out this series than by tackling some of the most stubborn challenges out there.

The technologies we feature below propose solutions falling into two broad themes: clean water and material inputs. Water contamination is an issue deserving far more attention than it often receives, disproportionately burdening disadvantaged communities across Canada and beyond with adverse health and livelihood impacts. Our second theme, material inputs, is one that holds significance for industries everywhere, from pulp and paper through to the research lab, as this week’s technologies demonstrate. The material inputs we choose matter greatly if we want to stop our landfills from overflowing, microplastics from seeping into every corner of our systems, and, of course, our climate from changing catastrophically.

The solutions to these challenges are out there, and the four technologies below are here to prove it. What unites these companies is their ability to turn complex environmental challenges into opportunities for sustainable innovations. As we conclude this series, we are both amazed and inspired by the innovation we’ve encountered – their solutions are scalable, practical, and designed for the future. For the fifth and final time in this series, we encourage you to support Canadian cleantech however you can. By buying their products, amplifying their missions, and advocating for cleantech investment, we can turn their climate solutions into climate action.

.

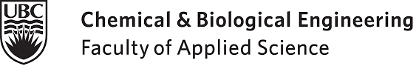

The University of British Columbia, Madjid Mohseni (Professor)

Company and product snapshot: Per- and polyfluoroalkyl substances (PFAS), commonly known as forever chemicals, have contaminated water supplies worldwide due to decades of fluoropolymer use, adversely affecting the drinking water quality for hundreds of millions of people. Addressing PFAS contamination has become a global priority, as many common PFAS are highly toxic and cannot be effectively removed by existing technologies. Madjid Mohseni and his team in the Department of Chemical and Biological Engineering at UBC have developed a novel adsorbent technology capable of capturing a broad spectrum of PFAS—including short and long-chain, anionic, cationic, and zwitterionic forms—enabling their complete destruction. The adsorbent, currently at TRL7, has been successfully validated through yearlong field demonstrations. It stands out for its reusable and regenerative qualities, offering a sustainable solution that reduces disposal burdens and appeals to environmentally conscious clients.

Who will be able to use it: With increasingly stringent regulations across jurisdictions and rising public concern, there is significant demand among water utilities, municipalities, contaminated sites, and various industries using fluoropolymers in their processes for effective solutions.

Market readiness: A UBC start-up is finalizing an exclusive license agreement with the UBC Industry Liaison Office. At the same time, efforts are underway to obtain NSF/ANSI certification for drinking water treatment applications. These steps will enable the start-up to begin commercial-scale manufacturing and implementation for water treatment applications by Q3 of 2025.

.

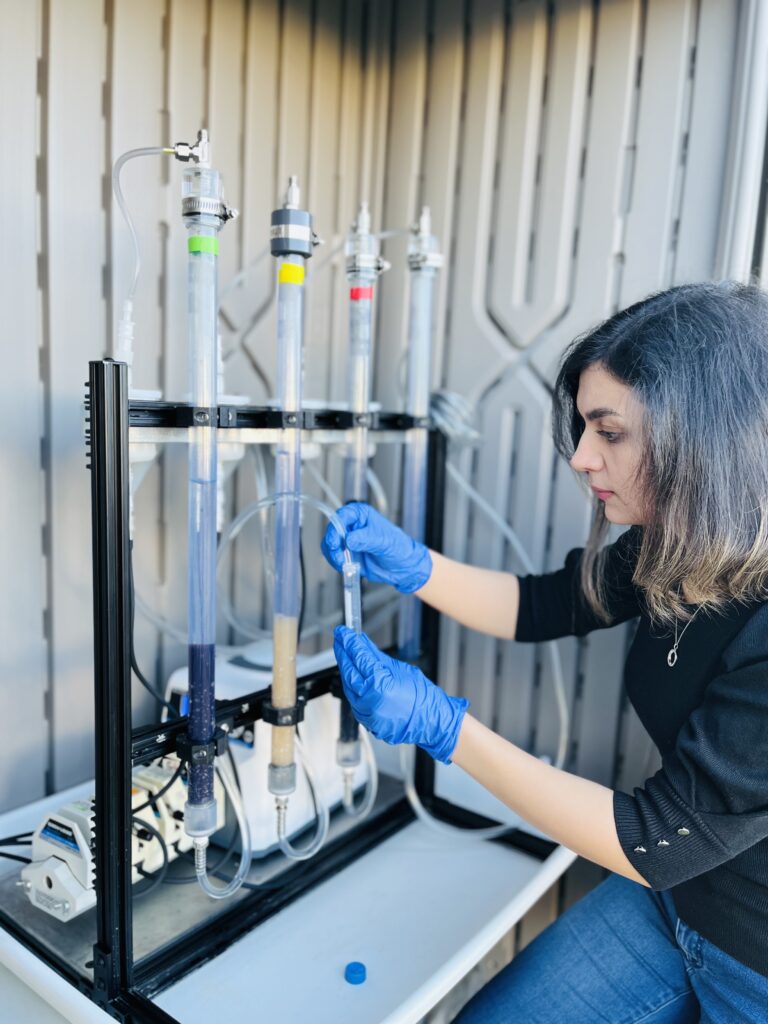

Xatoms, Diana Virgovicova (CEO and Co-founder)

Company and product snapshot: Headquartered in Toronto, Xatoms is on a mission to make clean water accessible around the world, inspired by the fact that women and girls around the world collectively spend 200 million hours daily in search of clean water. Xatoms understands that gender inequalities in many countries are deeply connected with clean water accessibility, because while boys go to school, girls are tasked with sourcing water. With projects in Kenya and South Africa, Xatoms is changing this narrative by offering clean and affordable solutions for communities without clean water. Xatoms uses AI and quantum chemistry to predict and develop novel photocatalytic materials that purify water by eliminating bacteria, viruses, and pesticides. The technology is reusable and powered by sunlight, making it accessible and sustainable, even for the most remote communities. Xatoms’ technology has the potential to reduce the energy required for water purification processes by up to 40%, decreasing greenhouse gas emissions and offering a sustainable solution to global water scarcity issues.

Who should use/buy it: Anyone needing access to clean water or wanting to help communities in need.

Market readiness: The technology is currently at technology readiness level 5 and is expected to be market-ready by Q4 2025.

.

BioLabMate Composite Inc., Sarika Kumari (Co-founder and CEO) and Sanjay Dubey (Co-founder and CTO)

Company and product snapshot: BioLabMate is addressing the untracked lab plastic waste generated in Canadian labs. During their Lab2Market program, they found that research, medical, and industrial labs generate roughly 5.5 million tons of plastic waste every year, contributing to issues like single-use plastic pollution and waste management and disposal challenges. Established in St. John’s, Newfoundland – the prime destination for sourcing quality seaweed – BioLabMate aims to replace the petroplastics conventionally used in research labs and clinical settings with seaweed-derived biobased and biodegradable bioplastic alternatives. In doing so, they will provide support for seaweed farming in Atlantic Canada, contributing to marine ecosystem health and aligning with Canada’s Net Zero 2050 target.

Who will be able to use it: The product will be utilized by research laboratories, clinical facilities, universities, and industrial research centers that are seeking sustainable alternatives to traditional plastic labware.

Market readiness: They anticipate the product will be market-ready by 2025, following the successful scaling of pilot production and thorough testing to meet industry standards.

.

HEJMAS Agrifibre Technologies, Marek Hejduk (CEO)

Company and product snapshot: HEJMAS Agrifibre Technologies is revolutionizing the pulp and paper industry with HEJMAS Blue Pulp – an innovation that produces the highest grade pulp from 100% agricultural field fibre waste, primarily industrial hemp. HEJMAS Blue Pulp is ideal for medical-grade and personal care products such as menstrual products, diapers, wipes, and surgical masks. This sustainable pulp is crafted through a patented process with reduced contributions to environmental concerns: it emits 88% less GHGs, uses 80% less water, and requires 70% less power than traditional wood pulp processes, and also avoids harsh sulfide and chloride chemicals. HEJMAS Blue Pulp is rising to global-scale challenges, finding novel ways to meet the growing demand for responsibly manufactured products while promoting environmental conservation.

Who will be able to use it: Target markets include manufacturers of medical grade, wound / personal / family care products such as menstrual products (tampons and pads), diapers, wipes, surgical masks and similar products currently made from tree (wood biomass) pulp. The product is particularly well suited as a raw material in these goods, as it has a far lower chemical content in production and has better absorbency than equivalent tree pulp.

Market readiness: They are in search of significant investments in order to build their first production mill. They have nearly completed process engineering on an identified mill site in Värmland, Sweden, and have supply chain (biomass) commitments from farmers within the desired 80km supply radius that will feed the proposed mill capacity and more. With the right investment, HEJMAS Blue Pulp will be in production within 12-18 months and profitable within 24-30 months.