Closing the Loop and Opening Possibilities: One Company’s Journey

In response to the climate crisis, some companies saw opportunities to reduce greenhouse gas emissions by integrating strategies from the circular economy model into their business, and by ‘closing the loop’ on organic resources to become leaders in transforming waste into a valuable resource. Niagara-based Walker Industries, with operations across Canada and the USA that include aggregates, paving and construction, emulsions, organics recovery, waste services and renewable energy, was one of the companies that took this opportunity.

Waste, by definition, means inefficiency. Walker takes the long view on waste materials: they see waste as a resource that still has value. For example, each year they recover over 565,000 tonnes of organic material such as leftover food, wood and construction waste and transform them to produce a variety of end-use products including compost, mulch, soil amendment, and energy.

Innovation in Motion

The extensive organics recovery business that Walker built began with its waste management operation at its Niagara Falls landfill. In 2002, they recognized that landfill gas, generated from the decomposition of organics in the landfill, could be captured to harness its methane gasses to make renewable energy and contribute to the low-carbon economy. On average, this offset project generated 350,000 tCO2e of carbon offsets annually, with the offset generation portion of the project ending in 2016.

The recovery of resources that were previously considered waste is not an easy feat. One of the biggest hurdles to resource recovery is odour. To address this, technologies that reduce odour are used which keep the communities that they operate within happy. Not only does the environmental impact of operations need to be considered, but the community impact must be addressed so that everyone may continue to enjoy natural resources as well.

Support for the Circular and Low Carbon Economies

Once one shifts focus to look at discarded materials as a resource rather than waste, opportunities to experiment with clean technology present themselves. Resource recovery is a clear contributor to support both the low carbon and circular economies.

For example, food waste is a serious issue that has far bigger impact than just our wallets. If food waste were a county, it would be the third largest emitter of carbon emissions, behind China and the United States, and roughly equal to the GHG impact of cement – accounting for 6 – 8% of human-made emissions. The recovery of food waste and other organic resources, helps close the loop on this global issue.

Think about your own consumption behaviour around food resources. Start with your purchase of food itself: Was it pre-prepared or packaged at the store? Will you consume everything that you purchased? What happens when food goes bad? Does your municipality have a green bin program in place to collect this material? How can waste collection and processing companies play a positive role in solving part of this issue?

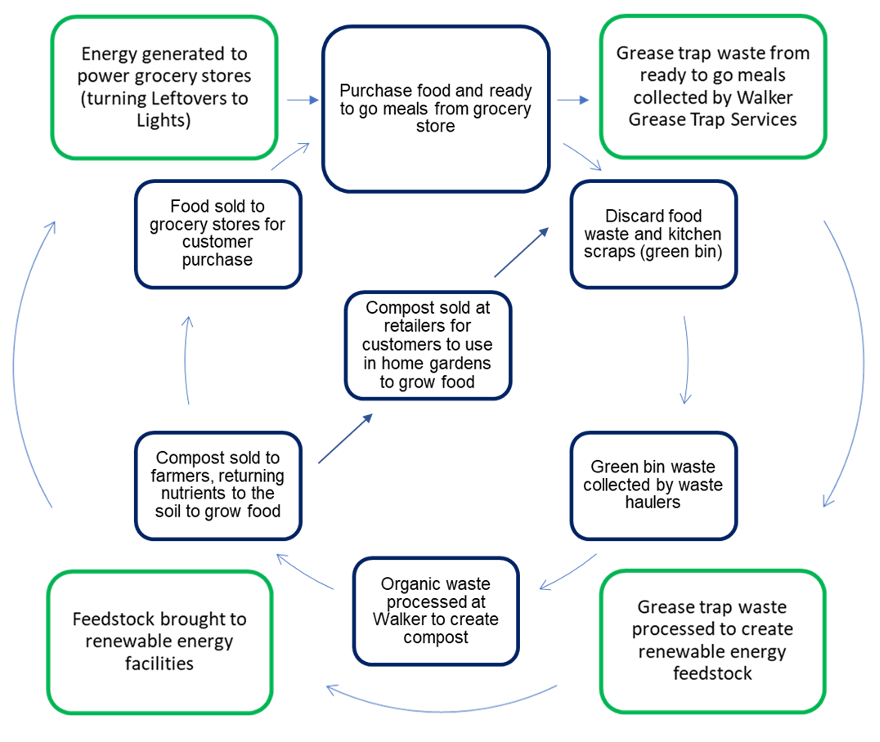

Food waste can be processed to create products that are either used in agriculture to grow more food, or as compost for individual consumers, often purchased from the same retailer the consumer originally accessed the food that entered the resource recovery cycle. The following flow diagram provides a simple overview of a process that contributes to a lower-carbon economy:

It’s Not As Simple as Setting Up a Backyard Composter

Proposed policy or legislation can either been seen as a risk or opportunity. In Ontario, when O.Reg. 79/15: Alternative Low-Carbon Fuels was proposed, Walker saw opportunity. A small team immediately looked at existing operations and determined the best way that they could actively new regulations that sought to use wood waste in place of fossil fuel sources. The first hurdle was to figure out how to collect and process enough wood waste resources and create the right products to help offset the long-term energy requirements for large industrial emitters like steel mills or cement kilns, and the second hurdle was to find a partner to demonstrate the feasibility of low-carbon alternative fuels.

Though it may seem simple to collect wood scraps, not just any wood waste can be used for this endeavour. Access to quality wood waste material that could be engineered into a usable product that would not risk the integrity of a potential future customer’s equipment was needed. Research into the energy potential of treated wood waste (e.g. laminated wood, rail ties and hydro poles) compared to coal landed Walker the solution to the first hurdle. Costs to reallocate equipment and human resources, revenue and regulatory hurdles (e.g. amendments to existing approvals) were also a part of the evaluation process.

In 2017, Walker was a successful applicant in the first round of a program established by the former Ontario government – the “TargetGHG program, Stream 1: Industrial Demonstration” funded by the Ministry of Research and Innovation and Science and administered by Ontario Centres of Excellence (OCE). With this funding, Walker entered a partnership with Stelco, a Hamilton-based steel company, to produce bio-carbon that can be used to replace a portion of coal used in Stelco’s coking process. This project is an excellent demonstration of how innovative approaches to resource recovery not only closes the loop on waste streams but also reduces emissions from high-carbon processes.

[Clean50 Editor’s note: In 2018 the incoming Ford government defunded most of these programs, defunded GreenON, and mostly defunded OCE. In the process, several projects that would have both enabled Ontario to produce the cleanest steel in the world, dramatically reducing the GHGs and pollution, and that would have demonstrated Ontario clean tech solutions at scale were lost, causing company failures, significant job and opportunity losses. The impacts continue: As Joe Biden and the USA contemplate a border carbon adjustment, Ontario made steel may suffer as a result. ]

The company has consistently provided low carbon solutions for almost 20 years – but their appetite for more continues to grow. With the goal of becoming completely carbon neutral, they are taking further steps to further look at their entire business through a carbon lens so that they may fully understand the business opportunities of the low carbon economy. Right now, by closing the loop, Walker has opened the door to more possibilities.