Graphene – From scientific discovery to real-world applications, with a Nobel Prize along the way

Standardized tests still require the use of a pencil…and not just any pencil, but an American #2 pencil. This pencil will have a lead that is not too dark and not too light, not too strong and not too soft. This # — “#2”, “#2-1/2”, “#3” and so on — is an indication of the strength or hardness of the pencil’s graphite core. The harder the core, the lighter the writing mark left on the paper. While many of you may not have used a pencil recently, you might recall that it leaves a slight residue on the page — graphite shavings. Now take these shavings to another level, and you have the world’s lightest, strongest, thinnest, best heat-and-electricity conducting material discovered to date – graphene.

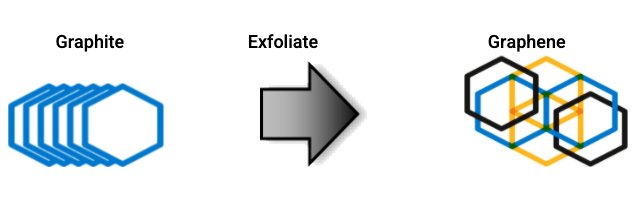

Graphene was the first two-dimensional material ever discovered. The University of Manchester found it in 2004, and the two professors who discovered it received the Nobel Prize in 2010. In fact, while people knew that one-atom-thick, two-dimensional graphene existed, it was Sir Andre Geim and Sir Konstantin Novoselov who figured out how to extract it from graphite. Their single layer of atoms in a honeycomb lattice model is what we are using today when we produce 6 – 10 atomic layers as our core business, a business based on research to develop the best thickness in terms of performance and production cost. The result is like carbon fibre on steroids but flexible.

Graphene is a non-carcinogenic material that is more conductive than copper and has high thermal conductivity, is flexible, bendable, extremely strong, and multifunctional. Graphene has the capacity to enhance certain properties within polymers that are unique to other commercially available carbon-based materials. This greatly improves mechanical properties by providing weatherability and making it an excellent barrier to UV, harsh chemicals, water and glass. We use our carbon technology to create a powder – GrapheneBlack™ powder. As a multifunctional additive, GrapheneBlack™ is an optimal replacement for conventional additives, particularly carbon black, improving product cost and enhancing product performance even at low-loading concentrations. In more relatable terms, you can add graphene to metals through compounding to reduce their weight and make them stronger – like a truck hood. Essentially, graphene-enhanced plastics and composite products improve performance and cost-effectiveness.

But it is not all about the powder. We want to bring graphene solutions to downstream applications. Sir Andre Geim and Sir Konstantin Novoselov received the Nobel prize because graphene improves performance in unique ways, not because it is a cool material. Think of it as a platform technology. We want to be able to use it. In fact, we need to be able to use it to see its full value and potential. It is not just about good graphene you can sell. We need to disperse it because it will not do it itself. Let’s take water, sugar and sand. If you put sugar in water and mix it, the taste of the water starts to change, and you taste the sweetness of the water – dispersion. But if you put some sand in the water and mix it, nothing is going to happen. Graphene is like that. It is naturally like sand. You need to disperse it, and when you do that, you unlock its properties. We want to be more than just the powder guy. Because nobody knows how to mix graphene, you have to do both, and we are focused on doing both.

From a sustainability perspective, we see all kinds of advantages and benefits. Production needs to be economical and efficient, so we have automated our factory to run with three people and the lights off. That said, we employ approximately 400 people and expect to add up to 2,000 jobs as we increase capacity and carry out other ventures. Automation provides us with a competitive advantage over carbon black producers making it possible to keep production costs lower while significantly benefitting our organization’s carbon footprint.

Second, as previously mentioned, in terms of products, we work with our customers to be the mixers. Generally speaking, there is a misconception about the recyclability of plastics. Most plastics are no longer recyclable after one use. However, GrapheneBlack™ technology makes it possible to extend the recyclability of plastics beyond one cycle without sacrificing product performance by adding a small amount of graphene. Our technology offers our customers within the plastics industry unique value and a truly sustainable benefit. Regulators force manufacturers to be responsible for the lifespan of the product – for example, pipes with a lifespan of 50 years. Graphene helps companies become more sustainable and address the circular economy.

Third, water re-use. The use of water is a critical component of our graphene process. To minimize the amount of water consumed by our new production plant, we will install a wastewater treatment facility. This equipment ensures that the water used in our manufacturing process will continually be re-used throughout our production cycles, dramatically reducing our local environmental impact. Our greatest strength lies in our clean technology.

So for us, using GrapheneBlack™ as a solution to Carbon Black is the key to our success. It takes a long time to get the right mix into a product, but once we achieve that goal, our customers are with us over the long term. Our cost structure is excellent. At high volumes, graphene production costs are low so the performance-to-cost ratio is very good. Finally, our organization is driven by a strong belief system:

- Bringing new technologies to everyday use

- Being a responsible corporate citizen

- Bringing new technologies to everyday use

This will allow us to create a better tomorrow by providing innovative, sustainable products and solutions across multiple industries and applications.

Dr. Soroush Nazarpour, Ph. D. Founder, President and CEO of NanoXplore Inc.