Green Value Creation Program©: A Tool to Accelerate Investments in Emissions Reductions.

As capital constraints and carbon pricing reshape investment decisions in Canada’s industrial sector, emissions reduction is increasingly framed as a value-creation challenge rather than a compliance exercise. Francis Fournier outlines how Kruger’s Green Value Creation Program operationalizes this shift by embedding greenhouse gas reductions into core capital planning. He argues that decarbonization succeeds when energy efficiency, asset modernization, and carbon regulation are translated into comparable financial metrics that allow projects to compete on business terms. Drawing on practical lessons from pulp and paper manufacturing, Fournier emphasizes disciplined project sequencing, cross-functional buy-in, and rigorous performance tracking as essential to turning climate ambition into durable industrial investment

In the manufacturing sector, the availability of capital to implement sustainability-related projects is often limited. Greenhouse gas (GHG) reduction projects compete, within the same budget, with all other investments, such as projects aimed at increasing production, improving quality, improving reliability, etc. In this context, to ensure buy-in from all stakeholders, Kruger’s Green Value Creation Program© (Green VCP) was launched in 2018.

The Company wanted to launch a program that would promote investments in CO2 emission reduction projects. Investing in reducing carbon emissions offers numerous benefits, and we wanted to focus on tangible and compelling goals.

Three objectives were central to the development and implementation of the projects:

- Reducing Energy Costs: Depending on the type of paper produced, energy can represent up to 20% of total manufacturing costs. Investing in energy efficiency projects not only lowers manufacturing energy costs but also leads to substantial savings on overall operating expenses.

- Asset Modernization: Replacing or modernizing aging assets to increase energy efficiency brings other operational benefits, such as increased reliability and technological advancements.

- Impact of Carbon Regulations: Regulations like Quebec’s cap-and-trade system for GHG emissions and British Columbia’s output-based pricing system can indeed be beneficial to the manufacturing sector. Reducing CO2 emissions faster than these regulations require can generate financial benefits when emission levels are below the regulatory cap.

These metrics enable project comparisons and prioritization within each location. At the Company level, investments can be directed to where they will have the greatest impact. Energy costs and CO₂ regulations differ from region to region, meaning the same project can yield varying benefits depending on its location. Throughout the planning process, it is crucial to sequence projects to meet or exceed overall GHG reduction targets.

Bring the Program into Action

Once the framework for the environmental footprint reduction program is defined, it’s time to take action. To start, it’s advisable to form a small, dynamic energy team within the Company to oversee the program. Its members must understand energy costs and both current and future carbon regulations. Additionally, being familiar with government and utility funding programs for GHG reduction projects can be beneficial.

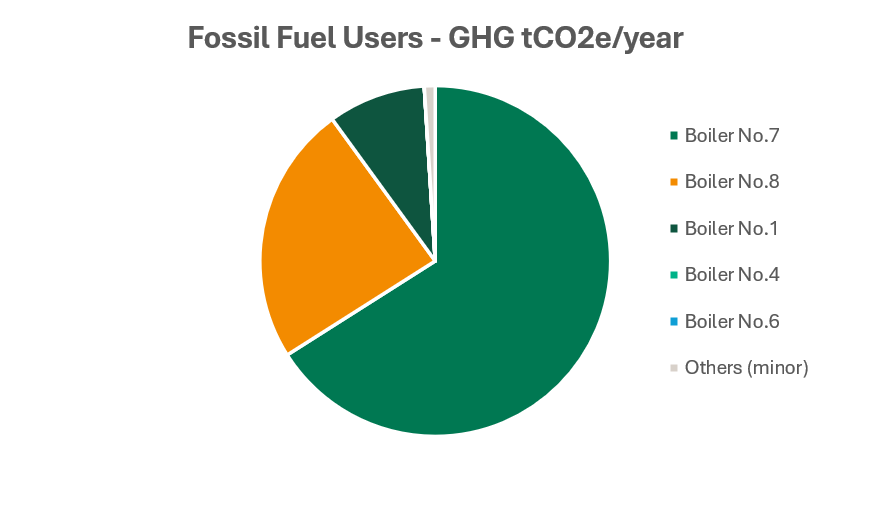

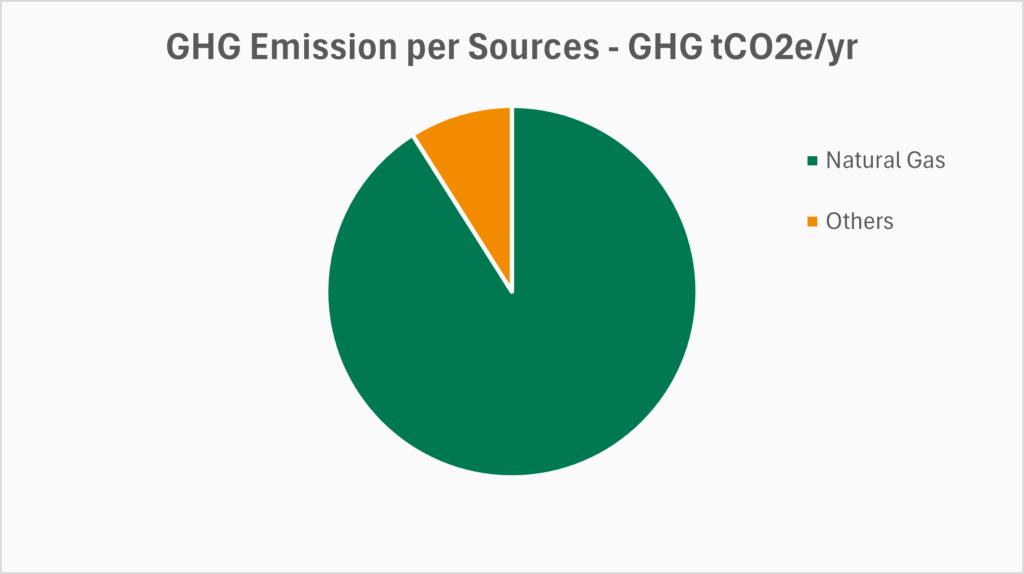

The next step is to collaborate with various teams at production sites, including production, maintenance, engineering, and accounting. Don’t wait any longer – teams love to come together to work on new initiatives. They have a wealth of valuable information to help you achieve your next priority: identifying the most GHG-efficient projects. Create a fossil fuel map for each site. This map identifies the types of fossil fuels used in the plant along with the systems or equipment that consume them. Keep it simple in the beginning. The information may already be available in accounting or some environmental reports. Sometimes, presenting the data in meaningful graphs is enough to guide teams and allow them to focus their time on areas with high potential.

In energy-intensive industries like pulp and paper, a process integration study is useful for identifying energy efficiency and other GHG reduction opportunities. The process is simulated using specialized software to analyze different scenarios. Since process integration requires advanced expertise, it is recommended to outsource this part of the development. Governments and utilities can provide funding for these studies. Equipment manufacturers also often propose new technologies. Stay informed about their development, as they can offer great opportunities. These steps should be facilitated by the energy team, with the active participation of the manufacturing teams. This is the fun part where we play with heat, steam, and emissions to identify the best solution.

Once a project has been identified, developed, and meets the program criteria, it’s time to allocate the budget and seek approval for its implementation. Funding from governments and utilities to support implementation will go a long way to make the project financially attractive. Make sure they’ve been factored into your business case. Additionally, consider including the GHG benefits, such as the value of carbon credits generated by the project. Once the project is approved, implementation can be managed by the site personnel, allowing the energy team to focus on other initiatives, such as adapting a similar project to another facility.

Lessons Learned

The human aspect of the program is as important as the technical and financial aspects. Below are two examples based on my observations.

- During the development phase, there is a tendency to assume that the project will meet everyone’s expectations, which is not always the case. It is essential to obtain all stakeholders’ buy-in, including those who will approve it. Sometimes, a few adjustments are enough to convince the majority. Learning late that a project has not been accepted undermines motivation and makes it difficult to maintain the emission reduction commitment, leading to further delays.

- Implementation can take 12-18 months, or even two years for larger projects. Following the project’s approval, the energy team focuses on other projects. However, collaboration must remain close. Regular briefings with the engineering team, who is in charge of implementation, and the production team, which will manage the project once it is completed, greatly contribute to maintaining adherence to the schedule. Consistent follow-up allows for the early identification of any deviations from objectives, enabling quicker corrections.

Don’t Overlook the Control Plan

In the past, the performance of many energy efficiency and GHG reduction projects was not tracked. Consequently, several projects experienced a substantial decrease in their anticipated CO2 reductions. To tackle this issue, CO₂ performance indicators for projects should be planned early during implementation and routinely monitored alongside other key performance indicators related to production, environment, and energy.