How Can Next-Gen Power Electronics Improve Energy Consumption and Contribute to a Carbon-Neutral Economy

Canada’s electricity demand is expected to increase significantly. Claude Vachet, Managing Partner at Cycle Capital, highlights how more efficient power electronics, particularly those using wide-bandgap semiconductors, are essential to manage the surge. Canada has a competitive advantage in semiconductor expertise, but increased startup capital and greater collaboration are needed.

A recent report from the Public Policy Forum forecasted that Canada’s electricity demand is expected to double by 2050, driven by the adoption of electric vehicles (EVs), electrification of industrial processes and increased use of electronics across various sectors. According to estimates from Natural Resources Canada, EVs will consume a significant 156.5 terawatt-hours of electricity annually by 2050 — equivalent to 22.6 per cent of electricity consumed in the country in 2020. To effectively manage this impending surge in demand, power electronics components used in industrial and consumer applications will need to become more efficient so utilities can save energy and supply power to meet demand.

For instance, a study from the American Council for an Energy-Efficient Economy (ACEEE) noted that to manage this impending increase in demand effectively, EVs, as an example, will need to improve their average efficiency from its 5.47 kilometers per kilowatt-hour (km/kWh) so utilities can better manage electricity demand in the years ahead.

Next-generation power electronics are an excellent solution to improve energy efficiency in electronic devices and contribute to a carbon-neutral economy. According to the U.S. Department of Energy, power electronics redesigned with wide bandgap semiconductors could cut power conversion losses, for example, in your laptop, – by up to 75-80% as well as shrink the size of your laptop power adapter to one-fifth the current size and cut its energy use about 20%.

“Next-generation power electronics are an excellent solution to improve energy efficiency in electronic devices and contribute to a carbon-neutral economy”

Claude Vachet

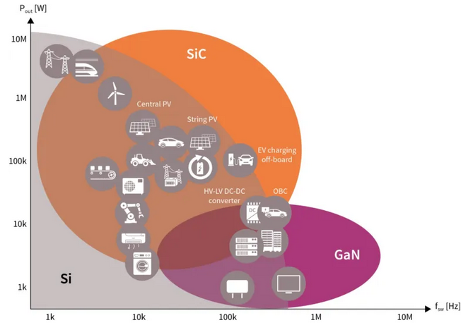

While traditional electronics have used silicon transistors, manufacturers are increasingly turning to new materials like gallium nitride (GaN) and silicon carbide (SiC). GaN Systems, a Canadian company that Infineon recently acquired, commercializes GaN power transistors, which offer better efficiency, higher switching frequencies, and improved thermal properties. This results in more compact and smaller power electronic systems to enhance efficiency and energy utilization in a wide variety of sectors (Figure 1).

Due to these attributes made possible by wide-bandgap (WBG) semiconductors, like SiC and GaN, future electronic devices would see lower power losses and more compact, smaller-power electronic systems to improve their efficiency and energy usage.

In the transition to a net-zero economy, the decarbonization of the electricity grid is pivotal to decarbonizing high-emission sectors such as manufacturing and transportation. As more renewable energy applications like solar photovoltaic (PV) systems are being integrated into the grid worldwide, traditional power electronic converters are conventionally used to convert the direct current output of solar panels into alternating current power for grid integration. With WBG semiconductors, these converters are better placed to maximize power extraction from the solar panels and enable optimal power flow based on the grid requirements.

Similarly, in motor drive applications, power electronics control the speed and torque of electric motors, enabling precise control and efficient energy usage. Employing power electronics can enhance energy efficiency, reducing energy consumption and lowering operating costs. As a result, WBG semiconductors will be critical to ensuring power supply meets the increasing demand and driving the efficiencies in other electronic applications.

“WBG semiconductors will be critical to ensuring power supply meets the increasing demand and driving the efficiencies in other electronic applications“

Claude Vachet

With this in mind, developing power electronic technology will be vital. Leveraging Canada’s expertise in semiconductors needs to be fully utilized along with broadening collaboration from corporate players and specialized investors to attract capital into innovative tech companies. In Boston Consulting Group’s latest report, Canada has a competitive advantage, particularly in materials and chemicals, to develop and produce technologies that can take the lead in scaling power electronic technology. This has the potential to concurrently support Canada’s goals to lead in net-zero manufacturing and climatetech technology.

But to advance next-generation power electronics to realize their full potential, Canada must ensure startup capital is available throughout the commercialization journey. This is because Canada currently trails its peers in late-stage funding, but this can be bridged through more involvement from the corporate sector and greater business R&D to promote innovation. According to TD Economics research, Canada ranks second-to-last in total R&D expenditure per capita. Specifically, private-sector R&D lags significantly, only accounting for around 50% of national R&D expenditures, while the OECD average is about 70%. As a result, for Canada’s next-gen power electronics solutions to take off in a globally competitive market, all stakeholders, whether its government, corporates, academia or startups, should leverage the country’s competitive advantage but also take steps to bridge the existing gaps to enable Canada’s climate tech solutions scale in the coming years.