Market-Based Solutions for Industrial Carbon Capture and Utilization

How can industrial emitters best utilize and create a market demand for captured carbon? The answer could come from an unlikely place – algae. Pondtech’s CEO Grant Smith outlines best practices for industrial emitters and how algae is changing the carbon market.

The Intergovernmental Panel on Climate Change, summarizing the world’s leading climate scientists research, recommends that the world achieve net-zero greenhouse gas emissions to avoid the worst impacts of climate change, and avoid a world defined by extreme temperatures, heat waves, fires, flood, droughts, and extreme weather.

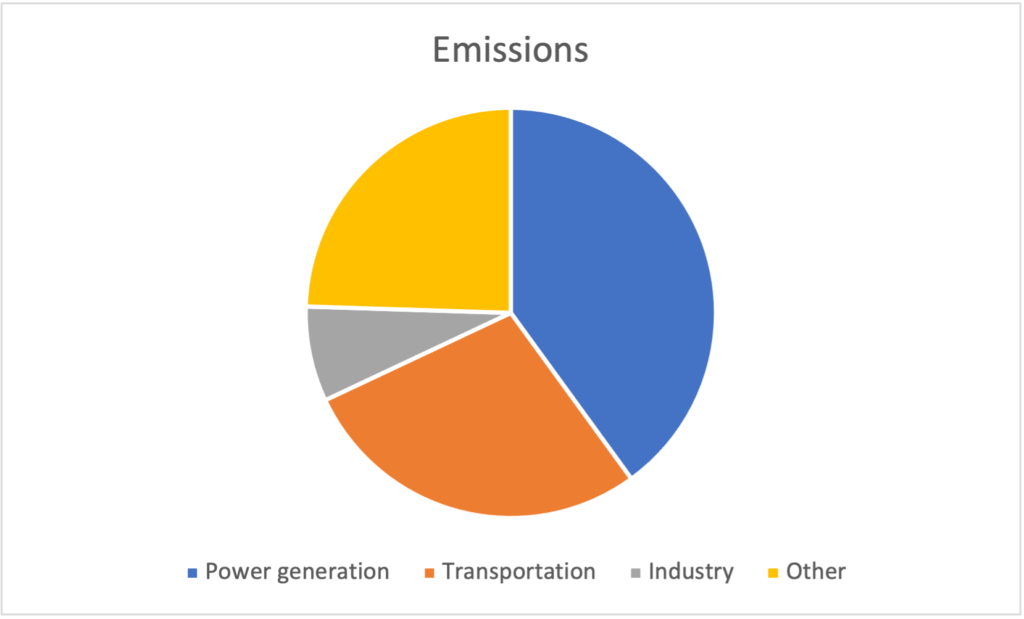

Since most global-warming greenhouse gas emissions come from the combustion of fossil fuels, this means changes in how we create and use energy in almost every sector of the economy. Canada emits 40% of its emissions from the combustion of fuels for heat or electricity, 28% of emissions from transportation, and 7.5% from industrial facilities (excluding electricity generators).1 Reducing emissions from electricity generation means generating electricity from hydro, nuclear or renewables. Reducing emissions from transportation likely involves a switch to electric or hydrogen fuels.

But industry is harder – there is no commercial technology to manufacture steel from iron, or cement from limestone, or to ferment corn into ethanol without emitting significant amounts of carbon dioxide. Almost every industrial facility emits greenhouse gases, often in large quantities. Cement plants, steel mills, power generation stations, refineries, chemical plants, manufacturers, ethanol facilities, fertilizer plants, will each emit thousands of tonnes of carbon dioxide.

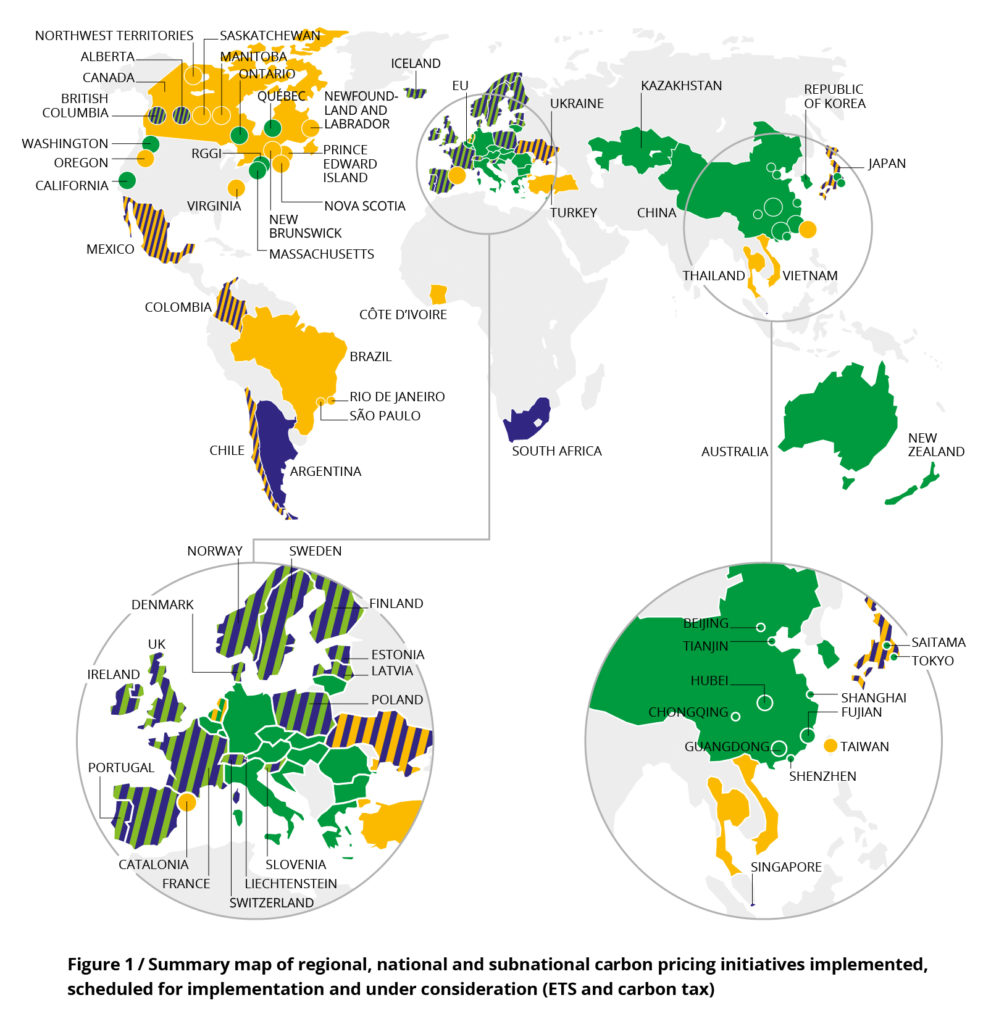

This has not gone unnoticed by regulators: according to the World Bank, globally there are 64 carbon pricing systems (either carbon taxes or emissions trading systems), covering ~21% of global greenhouse gas emissions. Just 5 years ago, there were 38 carbon pricing systems, covering 12% of global emissions.2

Many of these directly target industrial facilities – the largest emissions trading system by value, the European Union Emissions Trading System, covers 11,000 industrial facilities. Systems in China, Canada, California, New Zealand and the Northeastern USA add thousands more to this total.

Regulation is coming, but what do regulators expect industrial facilities to do? Even if all fossil fuel use at these plants was eliminated (not something that is currently technologically possible), the reduction of iron and limestone inherent to certain industrial processes would still emit millions of tonnes of carbon dioxide in Canada alone.

This is where new processes like carbon capture and utilization hold the most promise. There are essentially two possible steps in this process:

- Capture the carbon dioxide at site before it is emitted to the atmosphere. There are several technologies that can do this, including amine solutions, enzymes, and others.

- Determine what to do with the captured carbon.

The second part is less clear. Carbon dioxide can be compressed and pumped around and is often used to enhance the oil output of oil wells. This is inherently counterproductive – capturing emissions primarily from fossil fuel combustion only to use those captured emissions to increase fossil fuel production to eventually burn and produce more greenhouse gases does not get the world to net zero.

And yet, this is how most captured carbon dioxide is used, because the use of it to enhance oil recovery provides money from the sale of carbon dioxide to oil extraction companies. Financially, this makes sense. But a serious plan to reduce greenhouse gas emissions and get to net zero emissions cannot rely on increasing fossil fuel production.

For a few billion dollars and no financial gain, captured carbon can also be pumped deep underground, where it will turn into limestone in several years. The Shell Quest carbon capture project does exactly this. But there are real questions around the net emissions from this operation.

The carbon is captured and stored underground, but this process requires energy, which in turn emits more fossil fuels. The number of emissions from the process of pumping captured carbon underground, and the amount of total net benefits from this Quest project, remains unclear.3

“We can absorb carbon far faster than any natural ecosystem”

Grant Smith

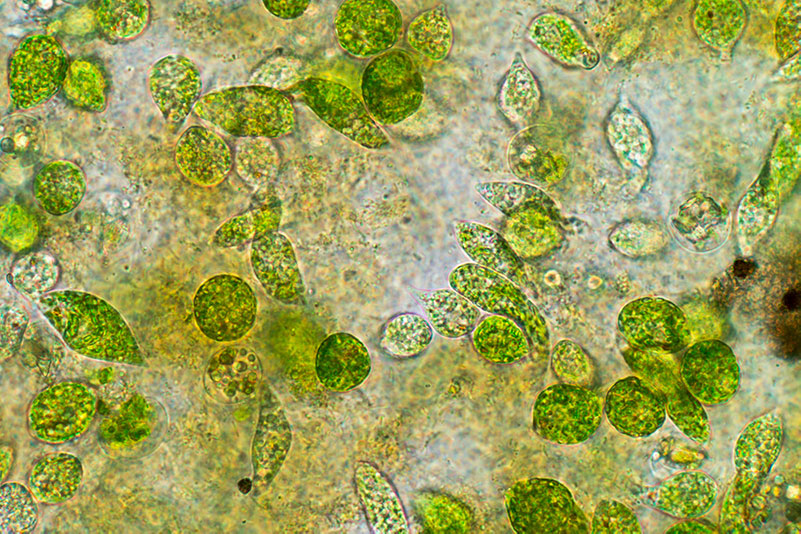

At Pond, we believe the best carbon capture and utilization solution is market-based. If we can create massive demand for products that can be made from carbon dioxide emissions, then industries become an asset for pushing the market towards net-zero emissions. Our proprietary technology is one such solution, using the power of algae to transform carbon dioxide emissions from industrial sources into valuable products.

Pond’s technology is conceptually simple – it is turbocharged photosynthesis. We bubble industrial emissions directly into tanks, where we add our illumination, nutrient, sensor, and control systems. Inside the tanks, microscopic algae cells use light, water, nutrients and carbon dioxide to transform greenhouse gas into organic sugars for energy, and carbon into algae biomass. This is the same process used by trees to absorb carbon, but because we are growing microscopic organisms in a three-dimensional space, we can absorb carbon far faster than any natural ecosystem.

Algae biomass has value and can be sold. Any health food store, pharmacy, and most grocery stores will carry powdered spirulina, a vegan superfood with a 65%+ protein content. To date, the markets for spirulina have been limited to health food and nutraceutical products, primarily due to cost. But Pond’s technology can dramatically undercut the volume and cost of incumbent growing technologies.

Algae, besides being a significant source of protein for people as spirulina, is a proven ingredient in cattle, pig, and aquaculture feeds. If these markets create demand for algae biomass, the potential for carbon abatement is huge. ~A billion tonnes of compound animal feeds are manufactured globally each year and the most common protein source, soybean meal, is only 40% protein. If algae-based feeds were to replace even a fraction of the current manufactured feeds, the potential climate benefits would be enormous:

- Algae produced from captured carbon would reduce potentially millions of tonnes of carbon emissions from industrial sites, providing a credible technology in sectors with hard-to-reduce emissions.

- Soybean production could be reduced, further reducing agricultural emissions, and reducing the conversion of forest into agricultural land.

- The world would have a sustainable protein source to help feed our growing population.

Perhaps most importantly, the climate benefits would be driven by market demand. The Shell Quest project referenced earlier cost $1.35 billion CAD. Funding was paid for by Shell (35%), and by the federal and provincial government (65%). This means that the project, which generates no return, is paid for by gas consumers and taxpayers. If carbon capture and utilization is funded by the market, through the substitution of soybean meal for algae biomass by animal feed companies, this is a better solution because the process will have little-to-no cost for consumers or taxpayers.