Luna Yu and Genecis: Turning Food Waste into Compostable Plastics

At 25, Luna Yu, Founder and CEO of the Toronto-based biotech startup, Genecis, is something of a compostable plastics prodigy. Luna and her team have both a plan, and a business plan, to turn commercial food waste into compostable, biocompatible plastics, called PHAs (polyhydroxyalkanoates), in a cost effective enough way that the use of this greener plastic becomes the norm.

At present, both producers and waste companies pay significant amounts of money to dispose of organic waste. Increasingly, many jurisdictions are enacting laws to keep food waste out of landfills, leaving waste managers with serious disposal issues thatGenecis’ invention can help solve in an everyone wins way. Luna, whose passion for Biotech/Cleantech work is inspired in part by her childhood in an industrial city in China, understood that that’s the kind of solution that’s needed.

Researching the matter, she found that there were promising output materials that could be made from food waste-derived Volatile Fatty Acids (VFAs) through acidogenic fermentation. PHA bioplastics in particular appeared to have large market potential – higher price per unit, high biodegradability, and comparable physical properties to existing petroleum plastics, all being assets. She was struck by the inherent unprofitability of biogas production to date, the slow growth of methanogens and low market value of biogas being issues. However, advancements in bioinformatics, genetic engineering and automation, suggested to her that there was business to be done here and she set out to make it hers.

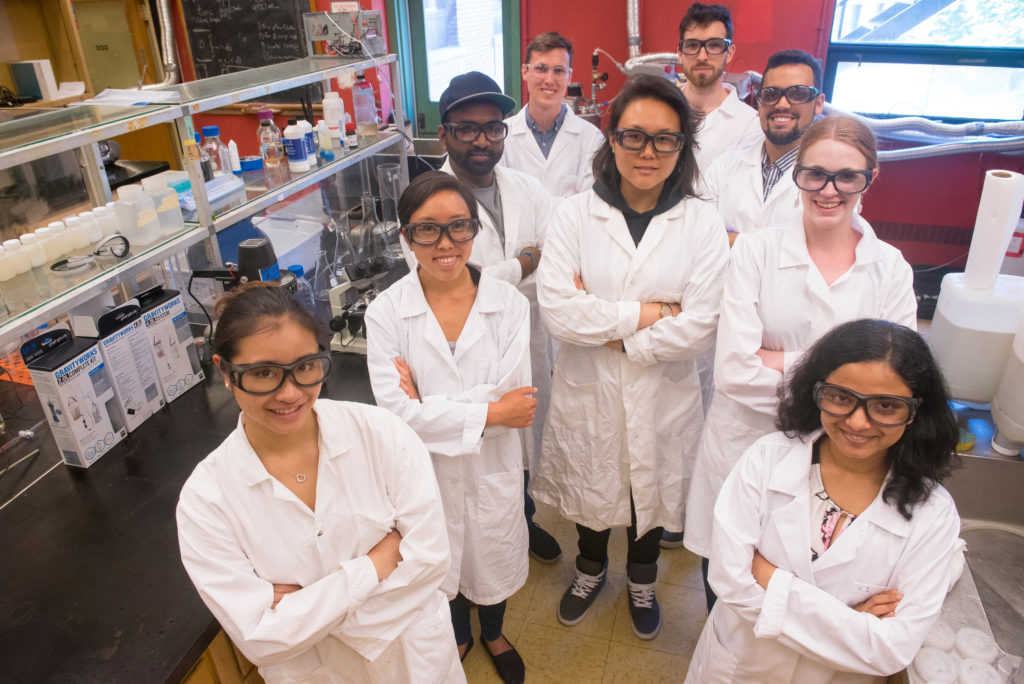

In late 2016, Genecis was incorporated. A team of talented individuals with backgrounds in biotechnology, engineering and programming soon signed on for a process that involved culturing bacteria species, ultimately leading to access to hundreds of novel bacteria not present in other databases. Extensive experimentation and prototyping paved the way to the production of Genecis’ first batches of PHA biodegradable plastics and since then the team has been focused on optimization and scaling up production lines.

They are now on their way to attaining purchase orders while collecting large amounts of data (and no small amount of recognition and attention as well as close to $870,000 in seed funding, pitch competition awards and investment ) on bacteria to build their own Synthetic Biology Platform, which, once completed should allow them to rapidly create new synthetic bacteria that makes higher quality PHAs, and other high value materials that are used in the cosmetic, pharmaceutical, and nanomaterials industries.