“One word: Plastics.”

“I want to say one word to you. Just one word: Plastics. There’s a great future in plastics. Just think about it.”

Advice to Dustin Hoffman’s character in The Graduate (1967).

From the stone age to bronze to iron, we are now in the age of plastics. While there are plenty of good uses for these flexible, light-weight, cheap, and varied materials, there is a massive problem from their overuse. If you look around your current surroundings, wherever you’re reading this, there are probably several different types of plastic you can easily spot – and even more that you can’t. From your phone, to what you’re sitting on, to even your clothes, it’s challenging to avoid plastic in this era. With the growing action on climate change and need to reduce CO2 emissions, it makes sense that plastic pollution is receiving more attention; plastic is, after all, oil. How can we claim to be acting to reduce carbon emissions and mitigate climate change if we do not address the plastic problem? This concern is how it all began.

I have been involved in environmental activism for almost all my life. Growing up near Lake Erie made the consequences of environmental mismanagement easy to see, with frequent E Coli outbreaks from algal blooms, fish die offs, and closed beaches. My brothers would joke the creek near our house would make you glow in the dark if you fell in and, while not true, it kept my concern about water quality high.

After finishing my master’s in Sustainability Management, helping homeowners to better protect themselves from flooding, I searched for a way to make a difference. I had gathered skills in behaviour change and water management, but wasn’t sure what was next. A water ‘hackathon’ was hosted at my alma mater (University of Waterloo) and the sound of a practical, real-world solution as an outcome was appealing. A focus area that year was Lake Erie’s plastic problem. I jumped right in.

This hackathon stretched over several months rather than several days, so I had plenty of time to learn just how bad the plastic situation was. It was here that microplastics came to my attention. These tiny pieces of plastics, less than 5mm in any direction, come from the breaking apart of larger pieces of plastic or fishing nets, from the plastic fibres in textiles (like polyester, nylon, spandex, etc.), from the ‘scrubbers’ in hygiene products, and from ‘nurdles’, which are small plastic spheres that are melted into other plastic products. These miniscule plastics wind up in waterways from mismanaged waste, from washing of synthetic textiles, and from litter. The plastic gyres you may have heard of in the Pacific Ocean are largely these microplastics, much harder to clean up than a plastic bottle off the beach.

What’s concerning about microplastics is that harmful chemicals build up on their surface, such as pesticides or dyes and plasticizers from manufacturing. In other species, the harm from microplastics and the chemicals that accumulate on their surfaces have been linked to all sorts of nasty endings, including hormone disruption, gut blockages, diabetes, and cancer. Since microplastics are so small, they are bypassing much of our existing filtration systems and are infiltrating our drinking water, in both tap and bottled water. Even beer isn’t safe!

It was shocking that this problem was so pervasive, and I had never even heard of it before! Worse, I couldn’t find any existing solutions that were proven to work. In midst of lamenting, “Why hasn’t anyone done anything about this?” I realized that that ‘anyone’ could be me. I could help get the plastic gone! With that, PolyGone Technologies was born.

PolyGone began by developing a washing machine filter to capture the plastic fibres that are released from synthetic textiles. Easier said than done. The amount of water flowing out the back of a washing machine is pretty high, which makes for tremendous pressure for a filter intended to capture plastic threads barely visible to the naked eye. What’s more, when my co-founder, Nicole, and I dug into the literature on microplastics, we couldn’t find any consistent ways to measure the plastics. There was a wide mix of measures, requiring expensive dyes and equipment. How could we know how well our filters were working if there wasn’t a way to measure the problem we were trying to solve? After many attempts and long days (and nights) in the lab, we were beyond frustration. We saw a few other filters on the market that we knew couldn’t be capturing all the microfibres from textile washing due to their large pore size, but we couldn’t prove it and they were already selling in any case. Maybe all this work building a science-based company, network, and fundraising had been for nothing. We thought about just giving up. We took advantage of a (timely) holiday break to step back.

Then it hit us.

No one had a consistent method to measure microplastics and current options certainly weren’t accessible to the average person. We could develop a method for microplastic detection that was reliable, easy-to-use, and affordable. In fact, we were already halfway there! We could use our method to test existing filter products and provide accurate results for the amount of microplastics in everyday consumer products. We started 2019 with a new drive, goal, and hit the ground running with our newest co-op student. By February, we had filed provisional patents for our process and were lining up our first pilots.

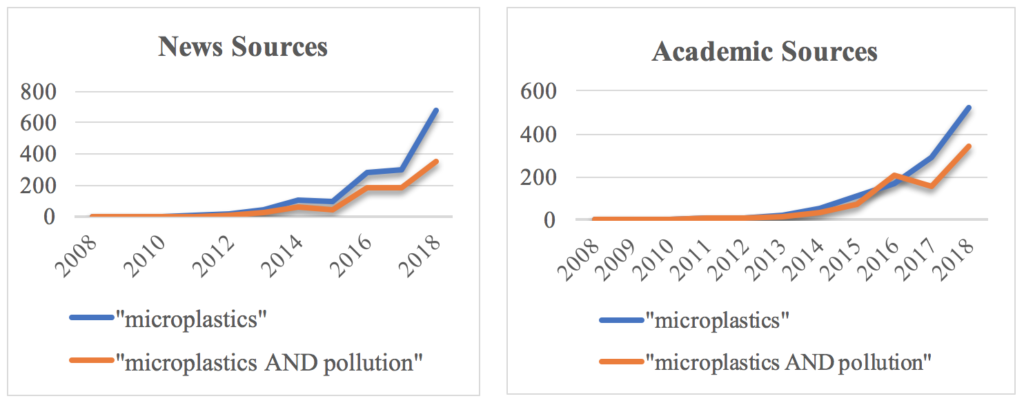

By this point, the ban on single-use plastics was gaining a lot of traction and plastic straws were disappearing left and right. Awareness of plastic pollution is growing but people are still unfamiliar with microplastics and just how common they are in everyday beverages.

I knew we had to incorporate awareness into our new direction. So, we have decided to focus on first providing a certification service for consumer beverages to let people know just how much plastic is in the products they love. At the same time, we work with the producers to let them know the likely sources of the plastic and how to best get them out. We’ve found key properties in plastics that reduces the need for expensive laboratory equipment, like an FTIR.

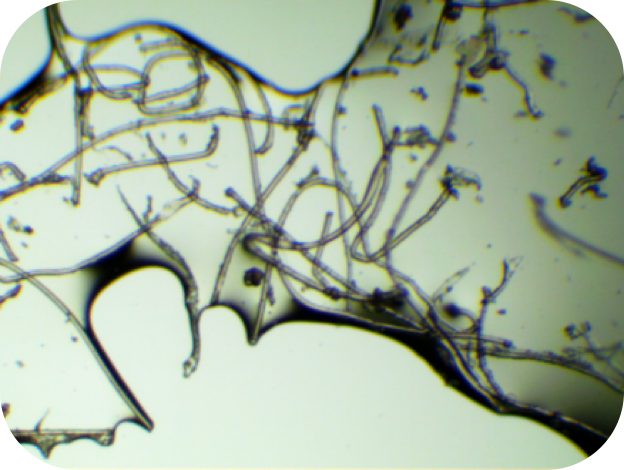

Our process is simple. We take a fluid sample (from your tap, your favourite beer, or even environmental samples), process it, and run it through laboratory filters to trap the microplastics on a background material. We then use our combination of dye and light to make the plastic particles ‘pop’ under the microscope. We’ve designed our own automatic image capturing process to photograph these filters and plastics and are developing software that automatically counts the plastics present.

Our system is largely automated, eliminating the need to count microplastics by hand. We are working on optimizing our prototype into something easy enough for a QA/QC lab to use, allowing beverage producers to analyze their samples in house. This saves them time in shipping samples to us, and reduces emissions from that transportation.

In part by good fortune, in part by personal interest, our first target market is the craft beer industry. Many folks creating those delicious craft beers care about the quality, integrity, and sustainability of their products. The best of the best are working directly with their local communities to improve the world around them. It fits perfectly with our values and goals – and is a great excuse to visit the breweries we love.

Perfect ending? Hardly. It’s still difficult work everyday and there are still many people out there who don’t understand the choices we make. Nicole and I aren’t just building a company to stop an environmental pollutant. We’re building a company that is engaging young folks that might be less likely to get involved in tech or STEM fields. We purposely strive to higher underrepresented youth, being a part of that group ourselves. We’re building a company that will not follow the norms of ‘start-up culture’ if that means compromising on our commitment to sustainability – or our commitment to balance. The narrative of working non-stop with minimal sleep, living off ramen and caffeine is itself unsustainable! Any company today, whether starting out or a long-time player, needs to consider the sustainability of their choices, from material selection, to shipment options, to target market region, to employee hiring and benefit policies. Climate change is impacting all manners of business. Smart investors will look for companies that understand that, or else risk losing their investment to a company that decided a coastline with rising sea levels was a good place to set up shop. Smart companies will adapt their practices now before losing out on customers that are choosing more sustainable offers (they already are!).

While not everyone in business ‘gets’ it (yet), they will.

“Adapt or perish, now as ever, is nature’s inexorable imperative.” H.G. Wells.

Lauren Smith is CEO and co-founder of Polygone Technologies