Paving the Way for a Truly Circular Economy in the Lithium-ion Battery Industry

As the transportation industry goes electric, fossil fuel extraction is replaced by the mining of critical metals for electric vehicle batteries. We have to better prepare supply chains to sustainably integrate lithium-ion batteries, and Zarko Meseldzija, Clean50 honouree and CEO of Recyclico, explains how.

The emergence of lithium-ion batteries and the first commercially available electric vehicles has initiated a shift towards sustainable transportation. This shift has prompted governments worldwide to divert their focus from traditional fossil fuels to critical metals such as lithium, nickel, manganese, graphite, and cobalt. However, as this transition from conventional fossil fuel engines to fully electric motors gains momentum, questions arise about whether this shift is genuinely better for the environment. In this article, we explore what needs to happen to create a truly sustainable circular economy within the lithium-ion battery industry.

1. Sustainable Production

Sustainable production extends to the manufacturing stage, where it becomes imperative to implement energy-efficient techniques and waste reduction strategies. By embracing innovative manufacturing processes, battery producers can significantly reduce energy consumption and minimize waste generation, thereby contributing to a cleaner and more environmentally friendly production cycle. These combined efforts coupled with sustainable energy sources, mark a pivotal step toward the development of sustainable batteries, which are vital for the future of renewable energy and electric transportation systems.

2. Usage

The usage phase of sustainable battery technology plays a crucial role in promoting a greener and more efficient energy landscape. One primary goal is to enhance battery efficiency and longevity, ensuring that batteries have a longer lifespan and higher energy efficiency. This not only reduces the overall environmental impact by decreasing the frequency of battery replacements but also optimizes resource utilization. Moreover, the integration of batteries with renewable energy sources like solar and wind power is pivotal. By enabling the storage of excess energy when the sun is shining or the wind is blowing, these batteries contribute to a more stable and reliable energy grid.

One example is the reuse of end-of-life EV batteries as secondary energy storage. EV batteries are considered “end of life” when the battery has depreciated to 75-80% of its original capacity. In this state, the batteries are still useful for secondary energy storage to stabilize energy output during times of low energy input. This synergy between batteries and renewables fosters a sustainable energy ecosystem, reducing dependency on fossil fuels and advancing the transition towards a cleaner and more environmentally friendly future.

3. Recycling

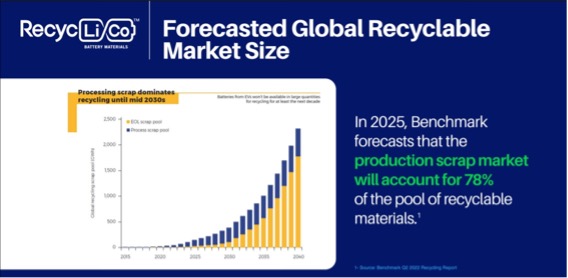

Recycling is a pivotal aspect of sustainable battery production and usage, offering significant environmental benefits. One innovative approach is in-house recycling, which involves recycling/upcycling production scrap within the manufacturing facility itself. This approach minimizes transportation emissions and fosters a closed-loop system by directly reintegrating manufacturing waste back into the production cycle. This is especially important as the current estimate for production scrap can be up to 30% of total lithium-ion battery production.

Furthermore, material recovery technologies are instrumental in this endeavor. These technologies aim to extract the valuable materials from battery waste, reducing the need for sourcing new raw materials. By building in-houses recycling processes, the battery industry can vertically integrate its supply chain and thus substantially decrease its environmental footprint, conserve precious resources, and promote a more circular and sustainable approach to battery production, ultimately contributing to a cleaner and greener future.

4.Policy and Regulation

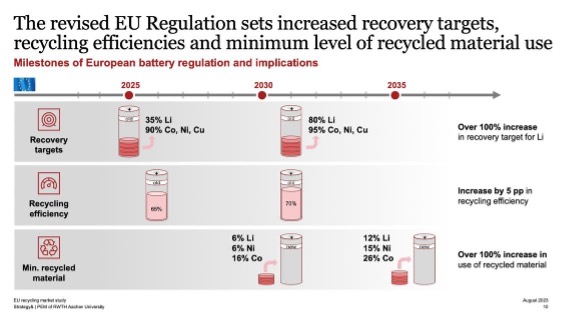

Policy and regulation play a pivotal role in shaping the sustainable trajectory of battery production and management. Governments can drive change by offering incentives to organizations that adopt sustainable battery production practices or mandate minimum recovery requirements, encouraging organizations to prioritize environmental responsibility. For example, Europe implemented an effective minimum recovery regulation where a certain percentage of battery material must be recovered with the percentage gradually increasing to encourage further technology advancement. Another regulatory strategy is the use of incentives ranging from tax benefits to subsidies, such as with the United States Inflation Reduction Act, which encourages mining, refining, and recycling of battery materials in North America.

Furthermore, the establishment of comprehensive standards and certifications is critical. Implementing the most sustainable practices in battery manufacturing and recycling ensures that these processes meet stringent environmental criteria. This not only enhances the quality and reliability of batteries but also fosters consumer trust in eco-friendly products. Overall, effective policy and regulation provide a framework that not only guides industry practices but also promotes a cleaner and more sustainable future for energy storage and usage.

5. Education and Awareness

Education and awareness are fundamental pillars in the journey towards sustainable battery practices. Experts in the field can play a pivotal role by sharing their knowledge and expertise, emphasizing the significance of a circular economy for battery materials. As end-of-life batteries are considered hazardous waste it is crucial to teach the public on proper disposal and handling practices to divert potentially hazardous waste entering our environment and reducing the risk of potential fires. By utilizing climate solution explainers and other outreach efforts, they can illustrate the environmental and economic benefits of adopting sustainable practices, motivating more organizations to take action.

Moreover, offering training and resources to businesses and institutions is crucial. By providing them with the tools to develop sustainable procurement plans and understand the advantages of a circular economy, it empowers them to make informed decisions that benefit both their operations and the environment. Ultimately, education and awareness initiatives are essential in driving widespread adoption of sustainable battery practices, propelling us towards a more eco-conscious and responsible approach to energy storage.

Conclusion

The transition to a truly circular economy in the lithium-ion battery industry is a complex journey for our planet’s future. Innovative manufacturing practices, highly efficient in-house recycling facilities, energy storage, effective government regulation, and public education to create a truly circular economy seems like an arduous task. Luckily, we are not starting from scratch, much of what has been discussed in this article is currently underway. The final piece of the puzzle lies in our collective commitment to utilizing these solutions.

As we enter the inevitable electric future, the benefits of sustainable battery technology will become increasingly evident. It is a journey worth taking, one that not only promises a cleaner and greener world but also underscores our responsibility to safeguard the planet for generations to come.