Hyper-localizing CPG with autonomous micro-factories

Projects Sponsor

Relocalize began its mission to eliminate the “chain” from the food and beverage supply chain with autonomous micro-factories. Their autonomous micro-factory for food and beverages––a world first–– is designed to eliminate 65% of supply chain steps and 100% of food miles upstream of retailer distribution centres. By delivering a greener local product, Relocalize de-risks retailers from stockouts, inflation and delivers a better, cheaper product, chain free.

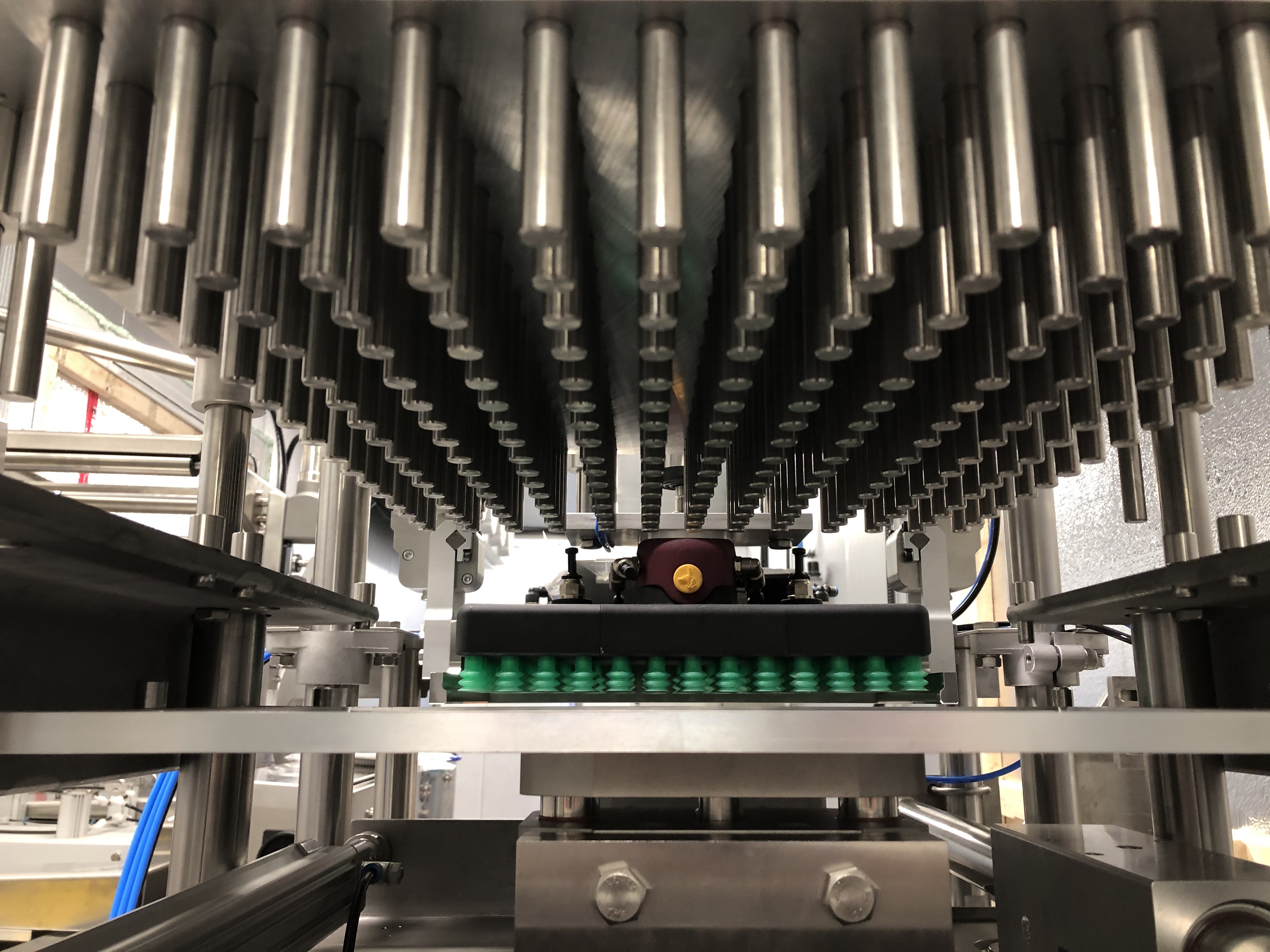

Worlds First Micro-Factory for Food & Beverages

Unsustainable supply chains are failing to deliver on retailer and consumer demand for green products. They’re too long, too complicated and too wasteful which means they’re also no longer economically or environmentally viable, especially for liquid products that are heavy and costly to transport.

Relocalize believes that heavy products should be made hyper-locally––less than 50km from customers. Deployable, autonomous micro-factories located at a distribution/fulfilment centre allows retailers to transform their supply chain from a centralised model to a distributed model. This would eliminate 100% of middle-mile transportation upstream of the retailer warehouse and it’s a shift where Relocalize is leading the way.

Their initial research focused on market and technology to identify a beach-head market that could be disrupted with a deployable platform. The retail packaged ice market quickly caught their attention when they discovered that packaged ice is a US$6B market in North America, dominated by three geographic monopolists. The whole ice castle, it turns out, is built on a centralised production and distribution model utilising largely the same technology developed eighty years ago. Ice is being made with antiquated technology that wastes up to 40% of the in-process water, then it’s distributed on a fleet of trucks on journeys of up to 1100 miles.

With all this, excess water usage, energy loss and transportation inefficiencies the Relocalize team realised this was a business practice begging for disruption. The old ways needed to be iced, and that great big US$6B industry could be shaken up with their platform.

Retail operators and consumers are dissatisfied with the incumbents and the Relocalize platform can deliver fresher, greener, cheaper ice. The team knew they’d found their beachhead market and that it was time to be the first mover to decentralise food and beverage manufacturing.

A technical feasibility study was undertaken from February to May of 2021. Its aim was to evaluate the feasibility of creating an autonomous micro-factory and to model CO2 reductions that would come from the shift. This study also looked at whether the technology could be cost-effectively deployed at distribution centres and the conclusion was absolutely.

A product market fit study was launched in the summer of 2021 to conduct a side-by-side market study of Relocalize ice versus the incumbent’s offering. No marketing or advertising was conducted, it was simply a side-by-side sales and feedback campaign to understand consumer feedback and preferences, and Relocalize ice got a far from chilly response. Within two months, they had outsold the incumbent 2:1 and in the third month they were well on our way to a 3:1 ratio.

That’s how you freeze the competition out.

Lights Out Food & Beverage Manufacturing

As each of these milestones were completed, other elements of the plan were initiated. Platform detail design was followed by a prototype build and test. The full-scale prototype build began in August 2021, testing started in Dec. 2021 and continues today. Notably, their launch customer, signed in January 2022, has agreed that they will initially serve seventy-two of their five hundred stores with the packaged ice Relocalize manufactures for them under their “Own Brand.”

In addition, Relocalize have built an extremely strong list of follow-on customers who all have expressed a deep interest in what they are doing. This includes offers to bid at North-America’s largest grocery and C-store operators.

Now in the final phases of build and preparation to deploy the world’s first micro-factory, 2023 will be the year to “Get Ready to Scale” for Relocalize. Two more systems will follow in 2024, and 2025 will see a ramping up of production and deployment capacity resulting in 49 systems being deployed by the end of the year.

In eighteen months, the Relocalize team has gone from a desire to transform the food and beverage supply chain to doing it. They’ve built the first ever micro-factory for food and beverages, proving the decarbonization impact of hyper-local distributed manufacturing. The estimated impact is the equivalent of 610,000 trees or 5,500 metric tons of CO2 annually per traditional factory replaced. A fully automated system that can make, bag, and palletize ice with no water wasted represents a 90% CO2 reduction compared to the incumbent and is a direct result of their patented horizontal freezing process.

Simply put, the Relocalize system delivers a greener, fresher bag of ice for 20% less than the incumbent, positioning them to take more than a chip off the old, wasteful block.

Looking to the future and beyond ice, Relocalize is confident that they have developed a modular, scalable platform that can be used to deliver the same impact for other heavy to transport products currently produced in a centralised production and distribution system. Think beverages, bleach and beyond.