Revolutionizing Marine Sustainability

The shipping industry faces pressure to reduce emissions. Mo AlGermozi, CEO at GIT Coatings, discusses their journey to creating a graphene-based hull technology that improves fuel efficiency by reducing drag and preventing marine growth without toxic chemicals.

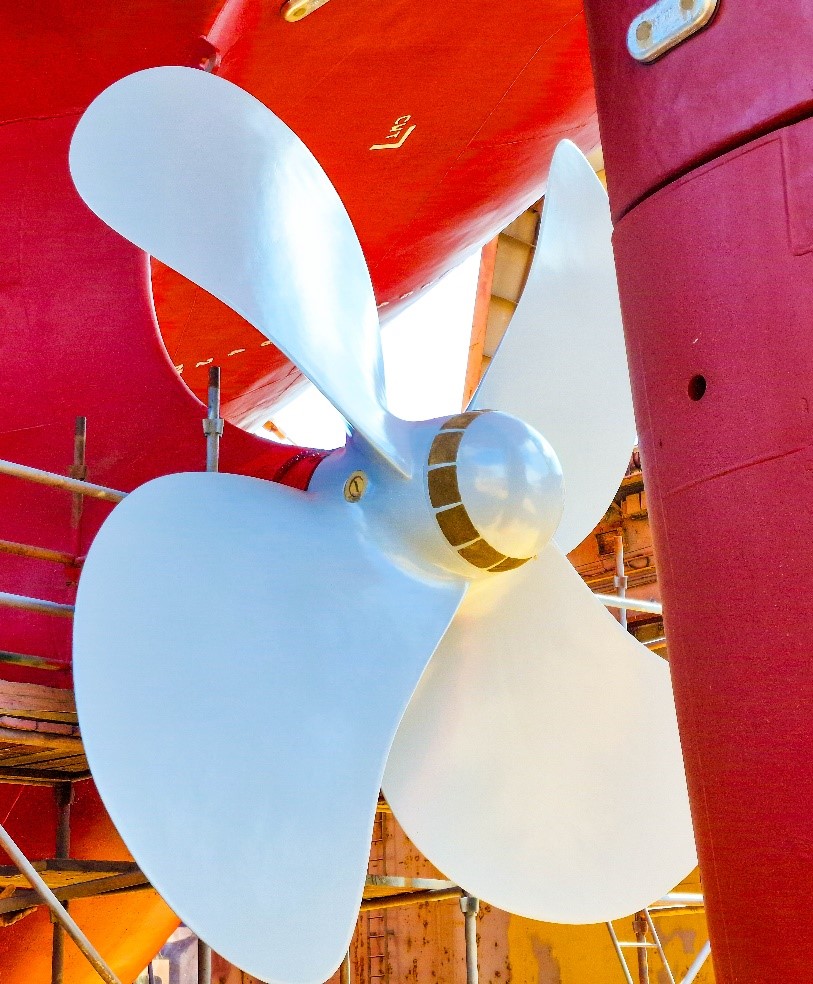

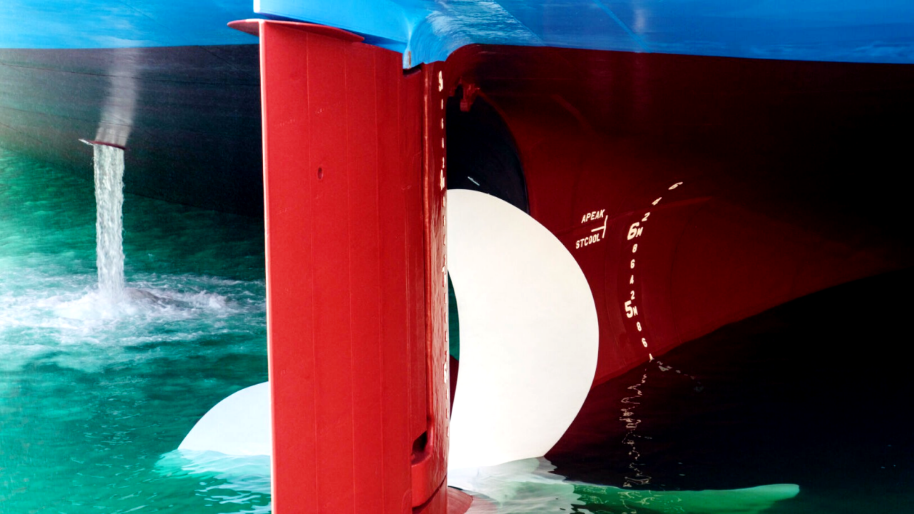

The shipping industry, responsible for transporting over 90% of global trade, is a key contributor to the world’s economy. Yet, it is also a significant source of carbon emissions with about ~3% of global GHG emissions coming from the industry. With over 6,000 large container ships and over 300 cruise ships circling the globe at any given time, the industry consumes an astounding 2,625 gallons of diesel fuel per hour, per ship. The carbon footprint from this fuel consumption alone is staggering, but the challenge doesn’t end there. Marine growth, such as barnacles and seaweed, attaches to the hulls of these ships, exacerbating the problem by increasing drag and reducing propeller efficiency. This seemingly small issue leads to a dramatic increase in fuel consumption, further contributing to environmental degradation.

“With over 6,000 large container ships and over 300 cruise ships circling the globe at any given time, the industry consumes an astounding 2,625 gallons of diesel fuel per hour, per ship”

– Mo AlGermozi

Aligned with the United Nations 2030 Sustainability Goals, the International Maritime Organization is targeting for 20-30% reduction in emissions in 2030 compared to 2008 which, given a moderate trade growth scenario, translates to a requirement of 76% reduction relative to the business-as-usual scenario in 2030.

Achieving this stretch target is challenging given the limited availability of alternative fuels. It is calculated that more than 30% of efficiency improvements are expected to come from energy saving technologies. Right now, the focus is on practical and proven solutions with immediate efficiency improvements that can “bridge the gap” towards green fuels and zero-carbon ships.

A ship’s hull is coming back into focus. Accounting for 20% of the structural design of a vessel, the hull has a significant impact on vessel performance and a smooth, clean hull can maximize operational efficiency. This can help shipowners and operators address IMO’s short-term measures such as the Carbon Intensity Indicator (CII), reduce fuel costs and carbon costs associated with the Emissions Trading Scheme (EU ETS) as well as improve the commercial attractiveness of their vessels.

The traditional approach to combat marine growth has been the use of toxic coatings, often containing copper and silicone oils, to deter sea life. However, these coatings come with their own environmental hazards. Designed to shed sea life over time, they eventually slough off the hull, causing damage to marine ecosystems, particularly in sensitive areas like harbors and coastal zones. In an era where sustainability is critical, a new solution was desperately needed. GIT Coatings, understanding the gravity of this problem, sought to develop a solution that not only improved fuel efficiency but also prioritized marine ecosystem health.

The challenge was twofold: create a coating that would reduce friction and prevent marine growth, while also being non-toxic and durable enough to withstand the harsh ocean environment. They created a graphene-based hard foul release coating as a hybrid patented technology that combines the best of both worlds: the smoothness and self-cleaning property of soft foul release coatings such as silicone and the mechanical durability of hard epoxy-based coatings. This makes it an ideal solution for significant fuel savings immediately after the coating application with a proven impact on EEXI, CII and EU ETS compared with traditional antifouling paints, as well as a proactive hull cleaning (grooming) with no paint damage and no risk for water pollution after repeated cleanings over the docking cycle.

Graphene as a nanomaterial is very interesting because it is 200 times stronger than steel; and they are using this material because it is enhancing the performance of the coating. High-performance marine coatings are one of best energy-saving technologies for vessel owners and operators and unlike other similar coatings, graphene-based coatings do not release any biocides and silicone oils in the marine environment. They also have lower VOC for applicators.

Marine transportation is more efficient in CO2 emissions per ton of goods shipped compared to other forms of transportation, such as trucks or planes. But the scale of shipping means even small inefficiencies can lead to enormous environmental costs. Marine growth on ship hulls creates drag, slowing down vessels and forcing them to consume more fuel to maintain speed. Studies estimate that up to 15% of a ship’s fuel consumption is caused by this increased friction. Multiply that across thousands of vessels operating 24/7, and the environmental impact becomes clear.

“High-performance marine coatings are one of best energy-saving technologies for vessel owners and operators and unlike other similar coatings, graphene-based coatings do not release any biocides and silicone oils in the marine environment”

– Mo AlGermozi

Over a decade ago two material scientists and now co-founders, Dr. Marciel Gaier and Mo AlGermozi, began developing the solutions to these ocean challenges. They were working together on graphene-based coatings in a lab at Dalhousie University campus in Halifax, Nova Scotia, Canada.

While focusing on aerospace applications and research projects for aerospace companies they discovered a significant technological gap in the maritime industry, which was using traditional coatings with toxic chemicals to tackle biofouling, or marine growth on ship hulls.

Realizing an opportunity to make the impact, they pivoted their focus to create environmentally friendly, high-performance marine coatings, aligning with the industry’s pressing move towards decarbonization.

Their initial market adoption was made possible through increased interest in globally relevant sustainable solutions in both the public, private and academic sectors in addition to their entrepreneurial efforts and hard work. Canada had identified oceans as a focus area for investment and programming. Thus, GIT’s early R&D was partially funded and supported through a variety of organizations across the growing Canadian Ocean Innovation Ecosystem. This included: Mitacs, the Creative Destruction Lab (CDL), Canada’s Ocean Supercluster (OSC), Atlantic Canada Opportunities Agency (ACOA), and COVE (Centre for Ocean Ventures and Entrepreneurship) to name a few, this speaks to their entrepreneur drive and efforts to engage with funding partners across the ecosystem.

In November 2020, the Smart Protective Coatings Project was launched at COVE in Dartmouth (Halifax) by Canada’s Ocean Supercluster (OSC) which brought together project collaborators: Horizon Maritime, Lloyd’s Register, Mitacs and project lead GIT Coatings.

The following year, Oceanex Inc. (Oceanex) a leading Canadian maritime transportation company also joined the Smart Protective Coatings Project. This helped GIT Coatings test, validate and market their products to a growing number of international transportation companies across the globe.

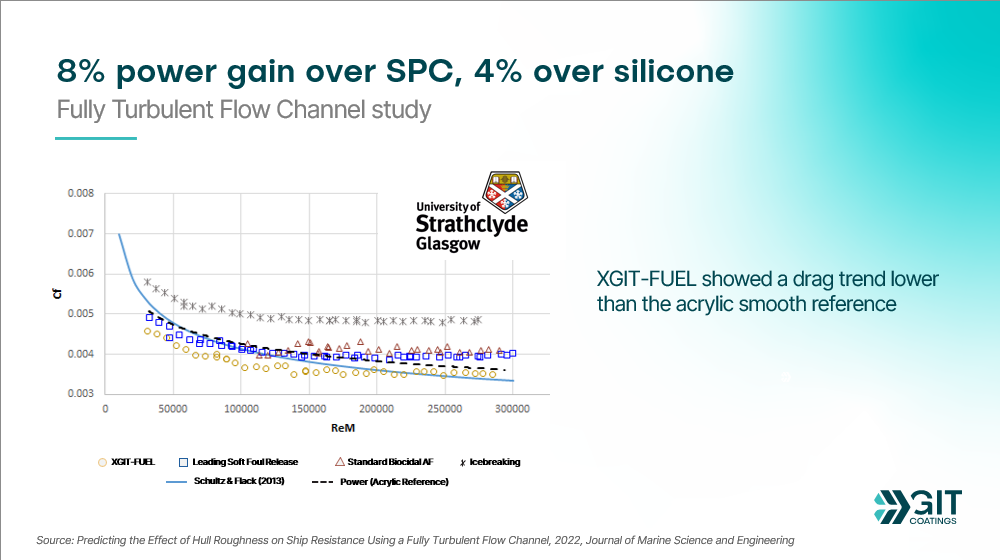

Through this project, Lloyd’s Register was able to validate the success of this project as it displayed consistent results at different speeds over eight months. In addition to this, a research study at the University of Strathclyde Glasgow demonstrated that GIT Coatings had produced a high-performing low-friction surface which resulted in up to 15% less drag than leading marine coatings.

Following the technical results and early-stage customer validation, GIT Coatings was able to attract a world-class venture investor syndicate to help finance its CAD$10M Series A in 2023, with participation from BDC Capital’s Climate Tech Fund (Canada), Seventure Partners (France), Stolt Ventures (UK), the corporate venture investment arm of Stolt-Nielsen, Farvatn Ventures (Norway) Invest Nova Scotia (Canada), and other new and existing investors. Then, the shipping industry started taking notice.

Over the past year, GIT Coatings has had an increase of 40% in paint applications worldwide on vessels compared to 2023 bringing our total vessels to over 400 by the end of the year. This even includes Halifax Transit’s Rita Joe Ferry which is decreasing carbon emissions, copper and plastics omitted to the Halifax Harbour every day, creating a sustainable and positive impact for their own community

GIT Coatings greatly reduce the number of biocides in our oceans. Their solutions are also saving the same amount of CO2 every day as a forest that is 122,305 acres. Through the implementation of GIT Coatings, the shipping industry has been able to avoid:

- +67,000 tons of CO2

- +118,000 kg of VOC

- +29,000 kg of Copper

- +550 kg of Silicone

This proactive approach in hull management by integrating low friction graphene-based coatings with state-of-the-art grooming technologies is a key player in emission reductions. This is aligned with the International Maritime Organization (IMO) emphasis on prevention setting a new standard in sustainable maritime operations by 2030 and even more aggressive goals by 2050.

This journey has been driven by a simple yet powerful vision: to create a world where shipping can be both efficient and sustainable. With each successful application and each new partnership, they move closer to that vision. By working closely with shipowners, sustainability leaders, and regulatory bodies, GIT is helping to shape the future of marine transportation. The lessons learned along the way – from initial research and development to large fleet agreements – offer valuable insights for others looking to drive change in their industries.