A Canadian View Into the Global Water Gap

Canada faces challenges in meeting the United Nations’ Sustainable Development Goals for clean water and sanitation, highlighting the need for improved infrastructure and the adoption of software solutions to enhance water treatment processes.

The global water gap is growing. By 2030, it’s estimated to reach 40% if current practices continue – that’s the discrepancy between the amount of freshwater supply and the demand for it. As a water-rich nation, this might not seem too worrying for Canada and its residents. However, water scarcity is increasingly becoming an issue around the world, and here at home too, especially as the effects of a changing climate are being seen more frequently in the form of droughts, floods, and intense storms that can cause further damage to already aging infrastructure.

“Water scarcity is increasingly becoming an issue around the world, and here at home too”

Devesh Bharadwaj

While 99.04% of Canada’s population has access to safely managed drinking water, there are currently 32 active long-term drinking water advisories for public systems on First Nations reserves. Even though this is primarily due to the state of the infrastructure available and not a lack of supply, Canada is not yet meeting the United Nations’ Sustainable Development Goals in this area, as well as many others where challenges remain.

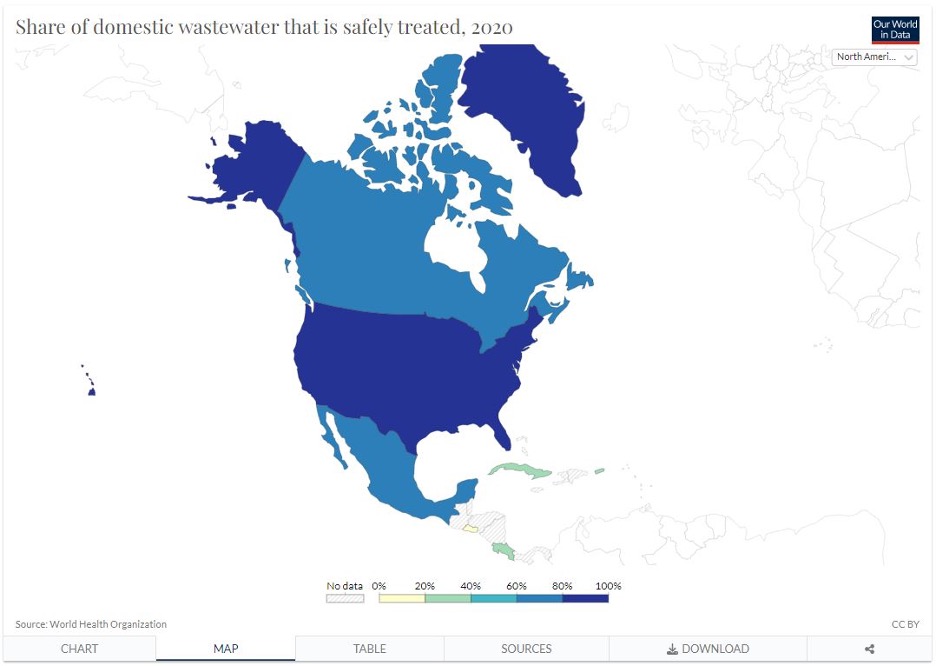

Goal 6 aims to “ensure availability and sustainable management of water and sanitation for all” by 2030. Wastewater treatment is another area that needs to be improved, with 77.06% of domestic wastewater being safely treated in Canada as of 2020.

The UN goals mean we have eight years left to reach 100% access to clean water and sanitation, while also working towards the net-zero targets that Canada’s federal government has committed to reach by 2050.

Water – from faucet to farm to factory

When thinking about water and wastewater treatment, most people think about turning the tap on or flushing the toilet. In places like water-rich Canada where water scarcity is not a top-of-mind issue, we often take for granted the fresh, clean water that comes out of the faucet or gets sucked down the drain. But this is just a portion of what the water and wastewater spaces look like, and it only really takes into account municipal treatment plants that are responsible for processing a region’s public water supply.

Water is a much larger component of our daily lives, even if it’s a seemingly invisible one. In fact, large quantities of water are involved in most agricultural, industrial, and manufacturing processes. Water is a key ingredient in every beverage we drink and a lot of the food we eat, both when growing crops and manufacturing processed foods. It plays a significant role in producing semiconductors, such as the computer chips that are in consumer electronics like smartphones, laptops, gaming consoles, microwaves, and refrigerators that most Canadians use every day.

It also is important in running infrastructure like that which powers the internet, with water being used to cool the countless servers that exist inside data centers around the world. In British Columbia, for example, water is also responsible for producing around 87% of electricity from hydroelectric sources.

The fact of the matter is that water touches most of the sectors and services we rely on; many of us just don’t know that it’s there. The vast majority of this water needs to be treated as both influent (the water that goes into a facility) and effluent (the water that comes out of a facility).

The water-food-energy nexus

Another fact that many people might not realize is that there is a direct tension between the way we use water today and the net-zero targets many of the world’s national governments and companies have committed to in the 2015 Paris Agreement. Water and wastewater treatment processes, as well as those used in desalination plants that remove salt from sea and brackish water supplies, need power to operate and there is an intrinsic relationship between water, food production, and energy use. When looking at the total across sectors, industries, and countries, water use, storage, and distribution make up about 10% of global greenhouse gas (GHG) emissions. This number is estimated to increase as the world’s population grows and demand increases alongside its growth.

“There is a direct tension between the way we use water today and the net-zero targets many of the world’s national governments and companies have committed to”

Devesh Bharadwaj

The question then becomes: how do we reconcile the need to increase access to a shrinking freshwater supply with the need to decrease the amount of energy we use to produce clean, safe drinking water and sanitation services? The short answer is that we need to start or continue implementing “quick wins” and incremental changes that lead us further down the path to net-zero. The longer answer is that we must make better use of advances in technology to help existing water treatment facilities operate more efficiently, with less risks and costs. The first step in getting there is to give operators and managing teams readily available access to the information they need to make the best decisions for a plant, balancing processes, costs, and environmental impact to sustain water supplies and increase affordable access to them.

Software catching up to hardware’s advancements

Hardware at these plants has improved over time to be more efficient and less energy-intensive, but the software tools that help operators manage day-to-day processes have not kept up. With the advent of cloud computing and technologies like artificial intelligence (AI), this reality has changed drastically in the last decade.

Analysis of how a plant is performing often requires operators to walk (or drive) around facilities with their pen and clipboard in hand to take sensor readings and check on equipment. These readings are then transferred into a spreadsheet that a process analyst or engineer works with, sometimes for hours or days, to reach a conclusion about how performance is trending. If a problem is identified with a piece of equipment or a sensor, it could take another few hours to days to investigate issues and perform maintenance. This causes delays in operational adjustment and can lead to the quality of water exceeding safe health or environmental compliance regulations.

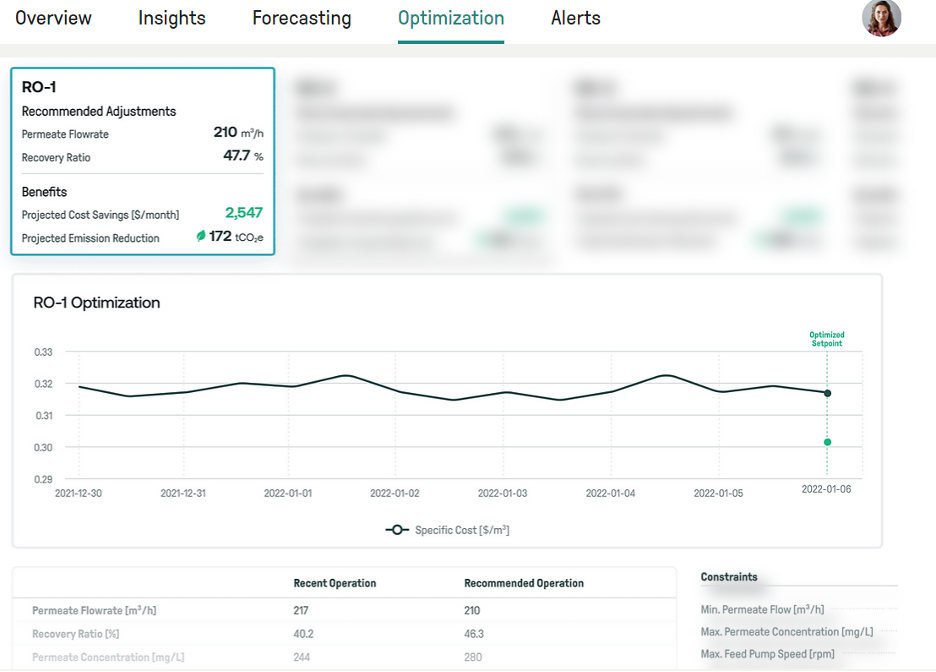

Cloud computing and AI are easy-to-adopt solutions for almost every treatment and desalination facility, both in Canada and at a global scale. Software tools like the Pani platform allow operators, process analysts and engineers, and managers to get a holistic picture of plant performance quickly, enabling them to make better, more accurate decisions when it comes to managing water treatment processes and facility performance.

Configured to each plant’s unique setup, infrastructure, and available equipment, the solution can not only help save hours poring over spreadsheets, but it can also help facilities reduce their energy and chemical consumption to lower their environmental impact, saving them on costs as they work to implement more sustainable business practices. Operational teams can return their focus to keeping processes running smoothly or conducting proactive maintenance and resource planning. Water supplies are secured for the future and production is maintained or improved safely, for both people and the environment.

A real-life example of digital transformation

One Canadian pulp mill that has started their digital transformation using Pani’s process operations AI treats the wastewater produced from their specialty fibre processing. The platform helps operators and technical and environmental managers manage the plant across shifts, while also ensuring water quality of the effluent is safe to be released back into a nearby river. The river is both a recreational spot for the local community, and an important economic source for a nearby First Nation.

By providing data from around the plant, including lab tests that check water quality and sensory data from equipment like membranes, pumps, tanks, and valves, operators are also able to spot issues before they become problems and do cleanings and servicing of equipment to maintain or extend the lifecycle of assets. Ensuring the water that flows in and out of the facility is managed properly is easier and faster since the team started using Pani’s process operations AI.

These increased efficiencies, in both operational team workflows and treatment processes, are possible at most facilities. The sooner software solutions are adopted, the more likely we will be to reconcile our thirst for water, now and into the future, with our obligation to reduce the energy consumed in treating, storing, and distributing it.

We all need water and it’s time we all became advocates for a sustainable water supply, in Canada and around the world.