Turning Pollution into a Solution

Pulling together a concept to make a meaningful and hearty difference is, admittingly, a challenge. Here’s the first step: Imagine that the industry and the planet that you love have a big problem and that you have a solution that can help. For us, the industry is aviation, the problem is climate change, and the solution is sustainable aviation fuel. Here is a resume of the challenges we face as an industry, how our consortium has developed a made in Canada solution and how you can help make it a reality.

FLYING IS FUN BUT CLIMATE CHANGE IS NOT

Pandemic aside, climate change is one of our greatest generational challenges. To avoid catastrophic events, we urgently need to decarbonize our economy to limit global warming to well below 2oC, and preferably 1.5oC, compared to pre-industrial levels.

Aviation is critically important to the interconnected global economy, enabling the rapid movement of people and products. It allows us to visit friends and family, have adventures, experience new cultures, and even relax in tropical paradises. However, the social and economic benefits of travel shouldn’t come at the expense of the environment. Climate change affects everyone, including airline operations which are highly dependent on weather. Increased turbulence, poorer aircraft performance, damaged infrastructure, and stronger storms are just some of the things that the aviation industry will have to deal with in the future.

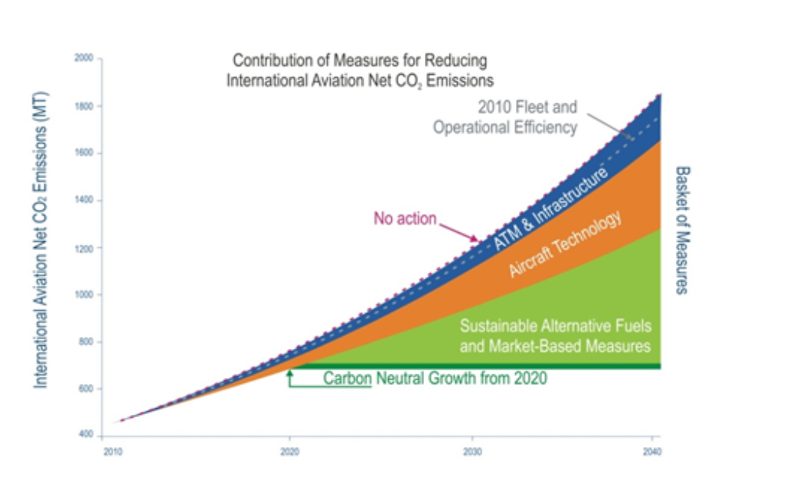

Currently, flying is responsible for a small percentage of global emissions; but, demand for air travel is growing rapidly. It is estimated that over 10 billion passengers by 2050 will travel by air, and if nothing is done, this could generate 1 800 megatons of CO2 emissions – up from about 915 million tons today. We must act now to reduce greenhouse gas emissions if we and our children want to continue to enjoy the privileges that flying offers.

AIRLINES ARE STEPPING UP TO THE PLATE

Recently, airlines have set some aggressive decarbonization targets, stabilizing emissions with carbon-neutral growth from 2019 and pledging to halve emissions by 2050. In fact, a significant number of airlines, representing nearly one-third of air traffic, have gone one step further and have committed to net zero in this timeframe. This aligns with the carbon neutrality objectives of many countries and regions. In addition, many airlines have set intermediate goals for greenhouse reductions between now and 2030-2035.

BUT AVIATION HAS LIMITED OPTIONS

Other industries have had low-carbon opportunities for years. Electricity can be produced using renewables and many transport modes can shift to electricity or use biofuel. Due to the nature of flying, aviation does not have these alternatives. Jet fuel has a combination of weight/energy density unmatched by electric batteries or hydrogen and can be safely used in a wide variety of temperatures and environments. Developing new aircraft and engine technology is expensive, complicated, and long. Aircraft have 25+ year lifespans before replacement. Additionally, regulations have to ensure that there’s absolutely no chance of anything going wrong while in the air – and for good reason! Due to these factors, hybrid and electric systems will not be available before 2030-2035 for short-haul flights and not until after 2050 for long-haul flying.

Since technology will not save us in the short term, airlines have limited options to decarbonize:

- Fly more efficiently and purchase new generation aircraft. Airlines have made significant fleet investments and improved fuel efficiency by 2% per annum between 2009 and 2020 but future gains will be incremental.

- Purchase carbon offsets from projects that reduce emissions elsewhere (Market Based Measures). For example, CORSIA (Carbon Offsetting and Reduction Scheme for International Aviation) will offset emissions growth on international flights. However, carbon offsetting cannot act alone and is seen as a temporary measure to gain time while the industry develops and invests in new technological innovations and sustainable aviation fuels to reduce CO2 emissions.

- Use sustainable aviation fuel as a liquid replacement for fossil fuels. It is a “drop-in” solution with a current maximum blend limit of 50% that is virtually identical to jet fuel, so it does not require new engines, aircraft technology or infrastructure. It can cut lifecycle carbon emissions by up to 80% and reduce other combustion by-products and pollutants. SAF has emerged as the best approach to rapidly reduce GHG emissions from aviation.

Although the benefits of SAF are undeniable, several big challenges must be overcome for it to be widely adopted:

Demand far exceeds supply: Massive quantities will be required to meet requirements over the coming years. There is a severe lack of supply with only two dedicated sustainable fuel producers currently in operation. It is important that all stakeholders; airlines, airports, OEMs, and governments support the growth of this industry. Currently, only 0.01% of jet fuel consumed is made from renewable resources. We will need 450-500 million tonnes by 2050.

Cost: Currently, sustainable aviation fuel is 2x-10x more expensive than traditional jet fuel. Fuel is the largest expense for airlines so switching completely to SAF is not economically feasible. We are in a chicken and egg situation. Prices will not come down until there is enough demand and there will not be enough demand until prices come down.

Competition from other sectors: Sustainable fuel refineries can easily switch production to sustainable fuel that can be used for road transport or in other industries. This is often more profitable, so producers need incentives to produce aviation jet fuel.

OUR INNOVATIVE PROJECT RECYCLES AIR POLLUTION INTO JET FUEL

Given the lack of supply, Air Transat realized several years ago that If we wanted to use SAF we were going to have to help develop it ourselves. For this reason, we joined the SAF+ consortium to find a solution for low-carbon flying. SAF+ Consortium Inc. partners include: CCG, Air Transat, Aéroports de Montréal, Parachem, École Polytechnique de Montréal, CIRAIG, CEPROCQ , Valorisation Carbone Québec Project and Hydro Quebec.

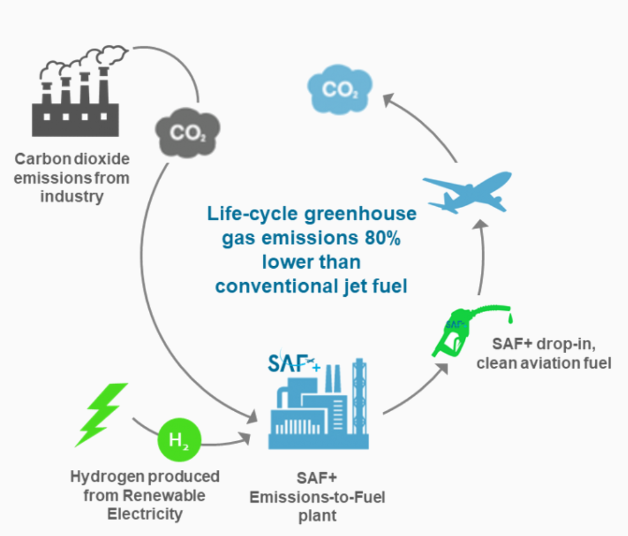

Carbon dioxide from industrial smokestacks is captured, combined with hydrogen produced from hydroelectric power and converted into synthetic fuel by a process called Fischer-Tropsch. This process is called power to liquid or by the even catchier “e-fuel.” It is the opposite of traditional combustion. Instead of burning jet fuel to produce energy, we apply energy to captured CO2 to produce jet fuel. It may seem like magic, but it isn’t.

Some of the key benefits of our process:

- For each ton of SAF+ fuel produced, we capture 2.7 tons of CO2 and avoid 100% of the emissions and impacts linked to oil extraction.

- One liter of SAF+ fuel needs only between 1.2 -3 liters of water, up to an 86% reduction compared with regular jet fuel.

- 80% lifecycle CO2e reduction as compared to conventional jet fuel.

- Virtually no SOx emissions, up to 90% less particulate matter and up to 5% less NOx than regular jet fuel.

- It is made with clean renewable energy.

- Our process avoids the pitfalls associated with some biofuel production processes such as land use concerns, food and water security, and feedstock availability.

- SAF is independent of fossil volatile fossil fuel prices.

- All the resources used to make the SAF are local.

- A key co-benefit of this project is the development of clean technology in an industrial part of Montreal East, providing jobs in the green economy.

Air Transat has made a significant investment in the project and has committed to purchasing a significant portion of the future production. Once completed, the plant will annually capture 200 000 tons of CO2 and produce 50 million litres of sustainable aviation fuel. The project is one of four finalists in the federal government’s “Sky’s the Limit Challenge” to develop clean fuel technology. It was also awarded the Solar Impulse Efficient Solutions Label which recognizes efficient, clean, and profitable solutions with a positive impact on the environment and quality of life.

WHAT CAN I DO TO HELP?

Building a SAF refinery is a massive investment that costs hundreds of millions of dollars and we will need many to be built in the coming years. For the dream to become a reality, all stakeholders, not just airlines, need to work together. In other countries, governments are investing heavily to incentivize SAF development and production. For example, in the US tax incentives for clean energy are part of the infrastructure and climate plan. In Europe, the ReFuel legislation is expected to stimulate SAF demand by proposing a blending mandate. In Canada, the upcoming Clean Fuel Standard may not incentivize SAF. Talk or write to your local MP or politician and ask that Canada support sustainable aviation fuel production. It will help achieve Canada’s climate goals and ensure that the marvel of flying and travel can be enjoyed by future generations. In addition, it will provide green jobs for the future. We do not want to be left behind by other countries. Finally, you can travel responsibly by flying on airlines that use SAF or by purchasing carbon or SAF offsets.

“Climate change is a huge challenge, but it can be brought in line if governments, businesses and individuals work together.”

Sir Richard Branson, Founder of Virgin Group